Lasers now touch almost every corner of automotive production. They’re used throughout all levels of the supply chain, from Tier-3 component and material suppliers to the world’s largest OEMs.

And lasers are now doing far more than just welding. Beyond structural assembly, they support battery manufacturing, power-electronics production, surface preparation, traceability, and a variety of applications that didn’t even exist a decade ago.

This article offers a high-level look at where lasers fit into modern automotive manufacturing. It also highlights the unique characteristics of laser processing – the factors that will keep lasers in the driver’s seat as the industry moves toward higher precision, greater automation, and the rapid growth of e-mobility.

What's So Special About Lasers?

Many industries today face the same set of underlying pressures. They must deliver products with higher precision, better quality, smaller form factors, and lower energy consumption. At the manufacturing level, they also confront higher throughput demands, stricter sustainability requirements, and relentless downward cost pressure.

Lasers have become such widely used manufacturing tools because they often support all these goals more consistently than alternative mechanical, thermal, and chemical processes. This is true because:

Lasers are non-contact: With no tool wear or applied force, laser processes stay consistent over time.

Lasers are highly spatially selective: A laser beam can be focused down to microns or expanded to cover several square feet, helping systems and operators place the energy only where it needs to be.

Lasers are coherent and bright: High power density enables deep penetration welding, fast cutting, clean kerfs, and minimal heat-affected zones.

Lasers are efficient: Lasers convert electricity into optical power with high efficiency and then couple that energy into materials with little waste, reducing heat input and post-processing.

Lasers are readily automated: Nearly every laser output parameter can be adjusted remotely in real time. This supports complex process recipes and rapid changeovers.

Lasers work with many materials: The same laser platform can often process steel, aluminum, copper, nickel alloys, coated steels, plastics, composites, and ceramics.

Lasers support advanced monitoring and closed-loop control: Process feedback – from simple power readings to inline weld-depth measurements – enables automated laser control, helping achieve superior unit-to-unit consistency.

Now, let’s take a quick tour of the areas where lasers are having the biggest impact in automotive manufacturing.

Body-in-White

Body-in-white is where lasers first entered automotive production in the 1970s, and their role has only expanded since then. Today they’re routinely used for high-speed welding, trimming, and tailored-blank production.

Laser welding is advantageous because it characteristically produces narrow, deep seams with minimal heat input. These reduce distortion, improve fit-up, and maintain tight dimensional tolerances in large assemblies.

Low heat input is especially valuable when working with today’s advanced materials, including high-strength and ultra-high-strength steels. These can warp, crack, or lose their unique mechanical properties under traditional welding methods. Low heat input also helps when joining mixed materials, whose differing thermal expansion and melting characteristics make them prone to distortion or cracking with conventional welding.

Lasers also support continuous, uninterrupted motion through on-the-fly welding and robot mounted scan heads. This allows manufacturers to eliminate stop-start delays and increase throughput.

And because laser processes are clean, consistent, and repeatable, they reduce rework and downstream inspection loads. Combined with inline monitoring for weld depth and seam position, lasers provide OEMs with a high-quality joining method that integrates readily into modern automated body shops.

Powertrain and Chassis Components

Lasers also play a growing role in the production of powertrain and chassis components, where precision and repeatability directly influence vehicle performance, durability, and safety. Many of these parts – transmission housings, drive-unit casings, cooling plates, mounting brackets, and suspension components – feature complex geometries and varying material thicknesses.

All these welding applications benefit from the tight thermal control lasers provide. Precision control over heat input helps produce strong, consistent joints with minimal distortion, helping manufacturers maintain alignment and mechanical integrity in parts that operate under continuous load.

Recently developed dual-beam fiber laser configurations push these advantages further by enabling spatter-free welding of cast and machined components – an application space once dominated by CO₂ lasers. Dual-beam lasers offer a clean, stable process which is especially important for assemblies that contain lubricants, bearings, or precision surfaces that must remain contamination-free.

E-mobility Battery Manufacturing

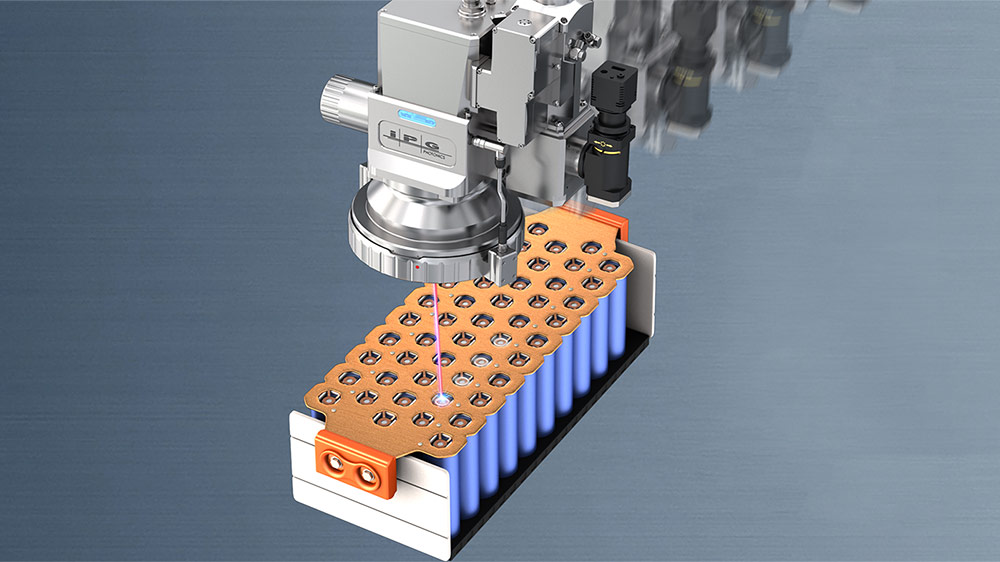

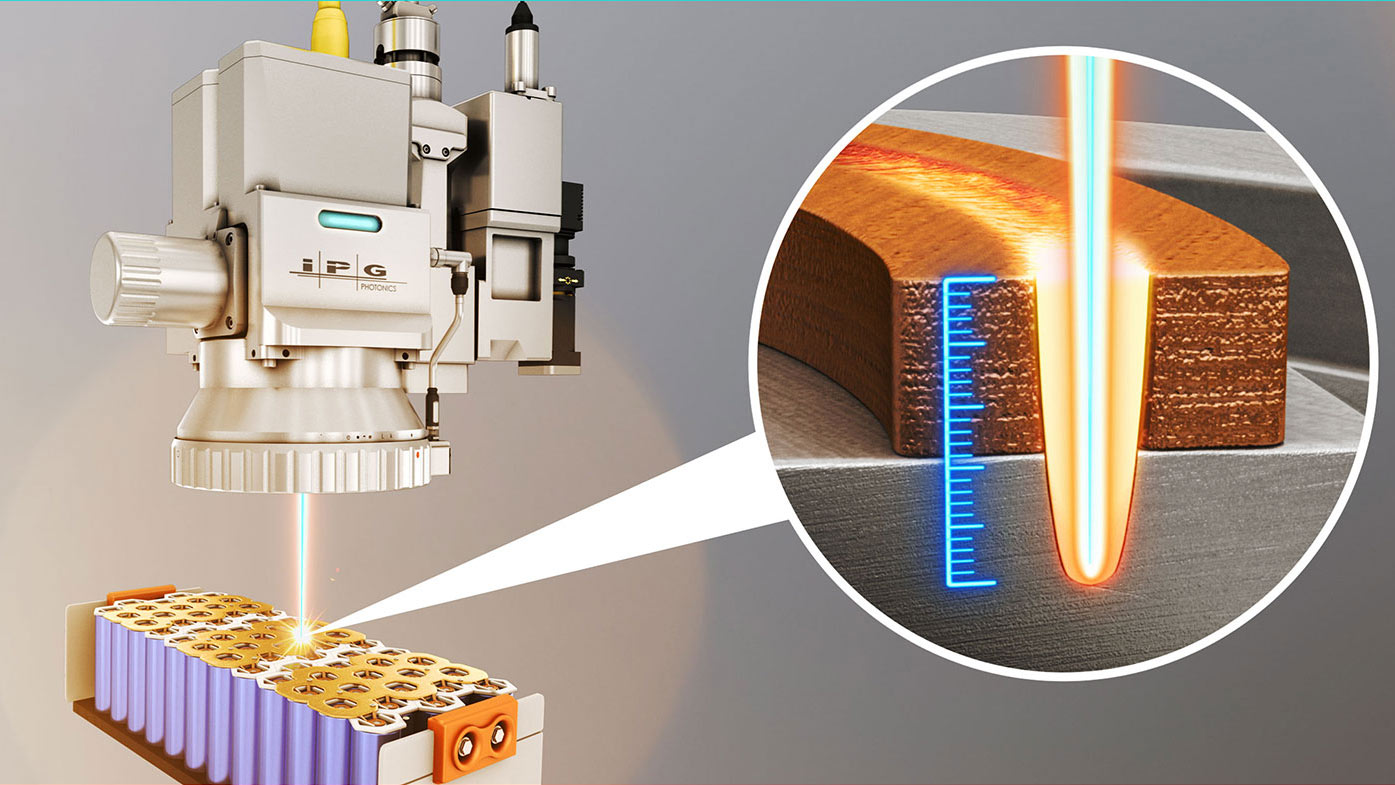

Nowhere has laser adoption accelerated faster – or played a more critically enabling role – than in EV battery manufacturing. Battery cells, modules, and packs all require precise, repeatable joining of copper, aluminum, and nickel components. All these materials are notoriously difficult to weld with traditional processes.

Lasers deliver the tight thermal control needed to form mechanically strong, low-resistance electrical connections. And they do this without damaging nearby separator films, adhesives, or insulation layers. They enable high-speed tab-to-busbar welding, foil welding, and precision cutting of current collectors with minimal burr or debris.

Dual-beam and wobble-beam fiber laser configurations are again essential here. Their use reduces spatter and minimizes porosity. This delivers consistent connection quality across thousands of joints per pack.

Innovations in inline optical monitoring further enhance process quality by providing real-time validation of weld depth, seam position, and consistency. All this gives EV manufacturers a scalable, high-yield process for building the cells, modules, and pack structures at the heart of modern e-mobility.

Electric Motors

Laser processing is valuable in the manufacture of EV traction motors, especially those built around hairpin winding designs. Their copper conductors must be precisely stripped, shaped, and welded to minimize electrical resistance and meet tight mechanical tolerances in the final assembled winding.

Lasers are often first used to remove enamel insulation cleanly and precisely. They can expose the underlying copper without mechanical contact, deformation, or thermal damage. These outcomes are difficult to achieve with abrasive or chemical stripping methods.

To create the final electrical connections, laser welding produces strong, low-spatter joints with minimal heat input. This protects nearby insulation, laminations, and epoxy potting materials. Dual beam – and particularly wobble beam implementations – further enhance gap-bridging and weld consistency, ensuring uniform performance across thousands of hairpins.

Interior and Trim

Lasers support a diverse range of interior and trim operations. They’re useful here because they combine precision and speed and often deliver a cosmetically superior result. Many plastic, fabric, composite, and coated components – especially those visible to the consumer – require clean cuts, tight perforations or hole patterns, or decorative features.

Mechanical tools struggle to create such edges without introducing roughness or deformation. Lasers deliver smooth, repeatable edges with minimal thermal impact. This improves cosmetics and reduces the need for downstream post-processing to restore appearance. Their ability to cut complex contours makes them ideal for instrument-panel openings, sensor windows, speaker grilles, and aesthetic perforations.

Laser marking, and especially day/night marking, is used throughout automotive interiors. It’s ideal for backlit buttons, switches, and trim pieces that require attractive, highly legible, and sometimes complex marks. Because it’s tool-free and compatible with a wide range of materials, laser marking facilitates rapid option changes and variant switching without retooling.

Traceability and Compliance Marking

The desirable properties of laser marking have led to widespread use in automotive traceability applications. Chief among these is the absence of contact or tool wear, which eliminates the risk of distorting delicate surfaces. And, because lasers can generate marks that are either extremely small or large, they support everything from micro-serialization to large, high-contrast identifiers.

The ability to control laser marking through software enables serialization or changes in mark content on-the-fly, without retooling. And since lasers work on metals, plastics, coatings, and composites, a single platform can mark many of the materials used in a vehicle.

Some of the key marking applications include brake components, airbag modules, and structural fasteners. These require durable, permanent identifiers that can survive heat, fluids, and vibration throughout the vehicle’s life. Electronics and housings, including control units, sensors, and power modules, need marks that do not damage internal components or compromise seals. And across the supply chain, serialization and data-matrix coding support part tracking, variant control, and compliance with industry and regulatory requirements.

Surface Cleaning

Lasers are increasingly used for surface preparation whenever tight control over material removal depth and preservation of underlying structures is important. Laser cleaning delivers this by removing rust, oxides, adhesives, and paint without mechanical contact or abrasive media. The process exposes a clean, uniform surface while avoiding the distortion, substrate damage, or inconsistent results that can occur with blasting or grinding.

Low heat input keeps surrounding material properties intact, which is important when preparing parts for welding or adhesive bonding. Lasers can even texture surfaces in controlled patterns to improve adhesion strength or promote wettability. Because the process is programmable, manufacturers can apply these treatments to specific regions without masking or fixturing.

Powder Coat Curing

The use of high-power diode laser systems for powder coat curing is just beginning to take hold. This is because laser curing offers several advantages over traditional convection or IR lamp ovens.

Because lasers provide localized heating, only the coated areas reach melt and flow temperatures. Narrowband infrared laser light is strongly absorbed by powder particles, which improves curing efficiency and minimizes bulk heating of the underlying part. The electrical conversion efficiency of diode lasers is also substantially higher than that of other infrared sources, meaning more of the input power goes directly into curing rather than being lost as excess heat.

Together, these characteristics make laser curing significantly faster and more energy-efficient than other methods. Plus, laser powder coat curing lends itself to inline process control to deliver highly consistent results.

Getting Started with a Laser Solution

While laser processing clearly offers numerous benefits, the best and most cost-effective results for a specific application are most readily obtained by partnering with an experienced laser solutions provider.

Developing or optimizing an automotive manufacturing process? Automotive projects often begin in our Application Labs, where we help develop, validate, and optimize processes before implementing and scaling them in production. As automotive requirements expand, IPG remains a committed partner for reliable, high-yield laser solutions.