Advances in laser welding, due largely to the applicability and affordability of high-power fiber lasers, have made it increasingly common in many manufacturing environments. Laser welding is very appealing due to its minimal thermal impact, speed, precision, and repeatability.

Despite its increasing ubiquity, laser welding is not free of challenges nor is it immune to weld defects. As with any form of industrial welding – such as arc welding, resistance welding, and electron beam welding – laser welding can be vulnerable to process inconsistencies that result in a bad weld.

It’s no surprise then that a variety of laser welding quality assurance (QA) techniques and technologies have emerged to detect, and even prevent, defective laser welds.

In this article, we’ll provide an overview of laser welding QA from traditional approaches to current monitoring and direct measurement techniques.

Defining a "Bad" Laser Weld

Put simply, a bad or defective laser weld is one that compromises the form, function, or safety of the end product. The first is not a common issue with laser welding, at least once process parameters have been dialed in. However, manufacturers must be diligent, particularly in micro-welding applications, to ensure that laser weld defects do not impact electrical efficiency, reduce long-term strength, or cause damage to sensitive components.

At best, weld defects disrupt the manufacturing process before it is completed, forcing manufacturers to rework or scrap valuable product – measures that cost both time and money. At worst, weld defects result in product failure and recalls.

Because laser weld defects come in a variety of forms, it is important to identify and understand them.

Lack of penetration: caused when the laser beam does not penetrate deep enough into the target material. Lack of penetration can cause strength and conductivity issues in the final product.

Over penetration: caused when the laser beam penetrates too deeply into the target material. Also called burn-through, over penetration can damage sensitive components in applications like battery welding.

Spatter: caused by instability of the molten weld pool, spatter is molten metal that often lands on and fuses to surfaces around the weld. Spatter can cause parts like batteries to short circuit, potentially leading to thermal runaway and catastrophic failure.

Porosity: porous laser welds are those that have gas bubbles or cavities trapped in the cooled weld. Porosity, which may reduce weld strength, can be caused by over agitation and rapid cooling of the weld pool.

Cracking: caused by rapid cooling and other metallurgical stresses, laser welding can result in cracking, visible or otherwise. Cracking is not always visible to the naked eye.

Lack of fusion: also known as incomplete fusion, lack of fusion occurs when the weld metal does not fully fuse to the base metal and can be caused by poor alignment or surface contamination.

Weld defects can largely be prevented by optimizing laser parameters and laser technologies. For example, dual-beam lasers use a core and ring beam to stabilize the weld pool, virtually eliminating spatter and porosity.

However, weld defects can still be caused by issues like poor fit up, contamination of the target material or optics, and degradation of laser components.

Traditional Laser Weld Quality Assurance

Traditional laser weld QA can be broken into two basic types: destructive and non-destructive.

Destructive testing relies on the destruction of a welded part to visually inspect and measure the quality of the weld. For example, in tensile testing a part is pulled apart until it breaks in order to measure the weld’s strength. Although less physically dramatic, acid etching is a destructive technique used to better understand a weld’s penetration, fusion, or porosity.

Destructive testing is typically time consuming, expensive, or both. Also, while very effective at measuring a weld’s quality, destructive tests by definition cannot be applied to every part or assembly. This means that their results must be make conclusions about an entire batch, resulting in unavoidable risk and uncertainty.

By comparison, non-destructive laser weld QA includes post-process methods like ultrasonic or radiographic testing that do not damage welds or parts. Ultrasonic testing uses mechanical vibrations that pass through the weld without significant signal loss unless an anomaly is detected, with greater loss typically indicating more concerning defects. Radiographic testing uses radiation to penetrate the weld and create an image of its internal structure, which must then be analyzed.

Technically, these traditional non-destructive methods can be applied to every weld. However, this is almost never feasible as it is too expensive and time-consuming. As with destructive testing, non-destructive testing must be used to infer the quality of entire batches of parts.

What is Laser Weld Monitoring?

Laser weld monitoring is an overarching term that refers to a variety of methods used to examine or gather information about the weld as it is made, a.k.a. “in-process” or “real-time”.

Laser weld monitoring is appealing because it is capable of providing data on every weld without slowing down the process and while eliminating the need for costly and time-consuming traditional QA steps. In-process techniques can greatly reduce uncertainty and are surprisingly cost-effective.

Types of Laser Weld Monitoring

There are a variety of laser weld monitoring methods with various advantages and disadvantages.

Acoustic emission monitoring: a method used to evaluate laser weld quality by converting sound waves generated during the welding process into electrical signals. Acoustic emission monitoring typically utilizes sensors on the surfaces of welded parts but non-contact sensors can be used as well. Analysis of acoustic data can be correlated with key weld quality indicators like penetration and cracking.

While somewhat versatile and easy to integrate, acoustic emission monitoring is susceptible to environmental noise and provides limited insight into actual weld features and geometries.

In-process radiography: the “real-time” equivalent of traditional weld radiography, in-process radiography can help visualize the behavior of the weld pool as well as the final weld.

In-process radiography is primarily used for research purposes, as this approach is expensive and difficult to utilize in productive manufacturing environments.

Image processing: using visible light or thermal cameras and machine vision, it is possible to produce images of the laser welding process in real time. This can produce detailed images of welds but may require multiple cameras to capture adequate detail. Even then, image processing does not provide a detailed view of internal weld geometries.

Optical sensing: optical sensing methods, which typically rely on spectrometry, pyrometers, or photodiodes, capture light and convert it into data about the laser welding process. While these methods produce more data than some laser weld monitoring methods, they rely on indirect weld indicators like reflected light, temperature, and weld plume rather than examining actual weld geometries in detail.

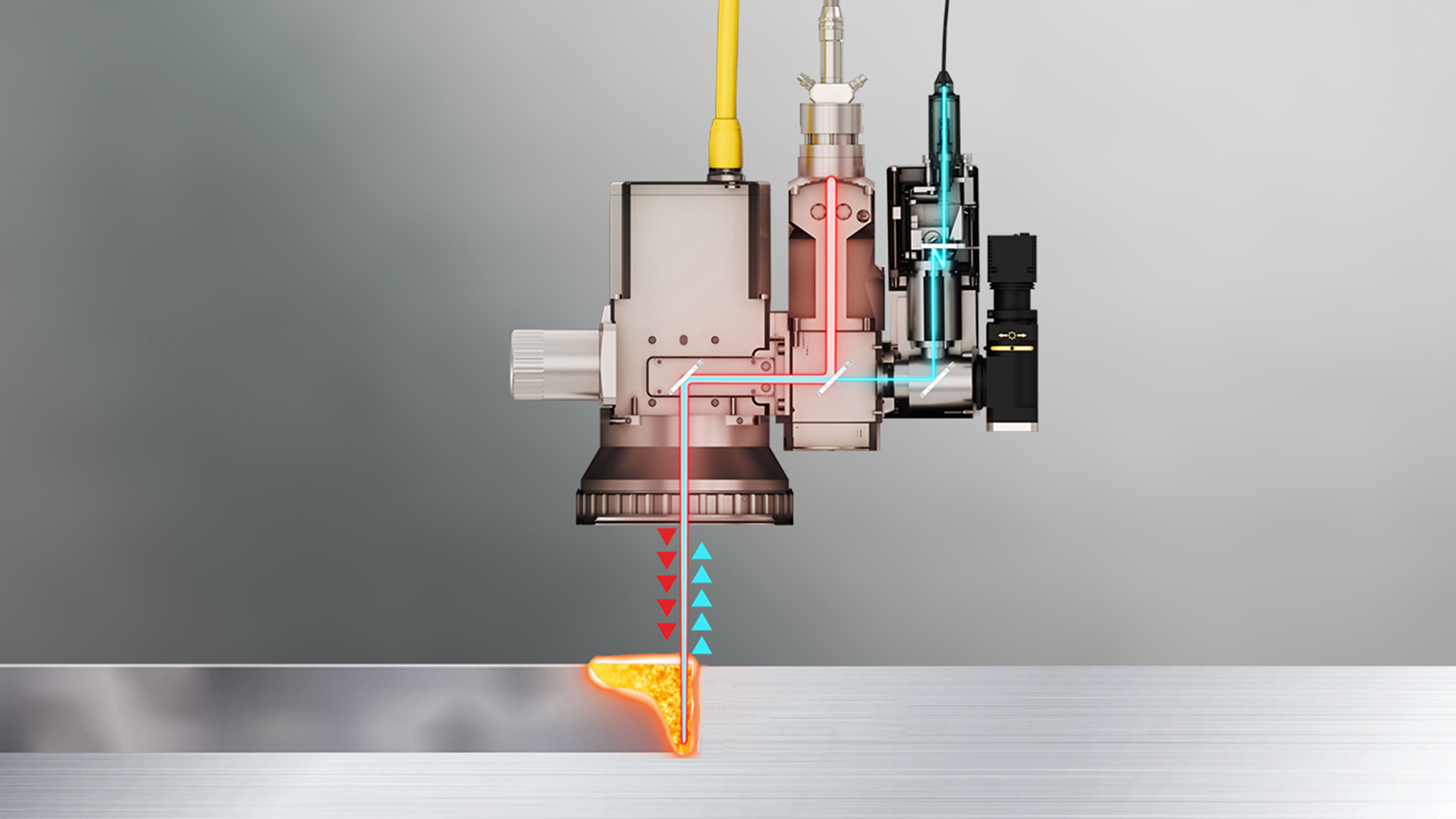

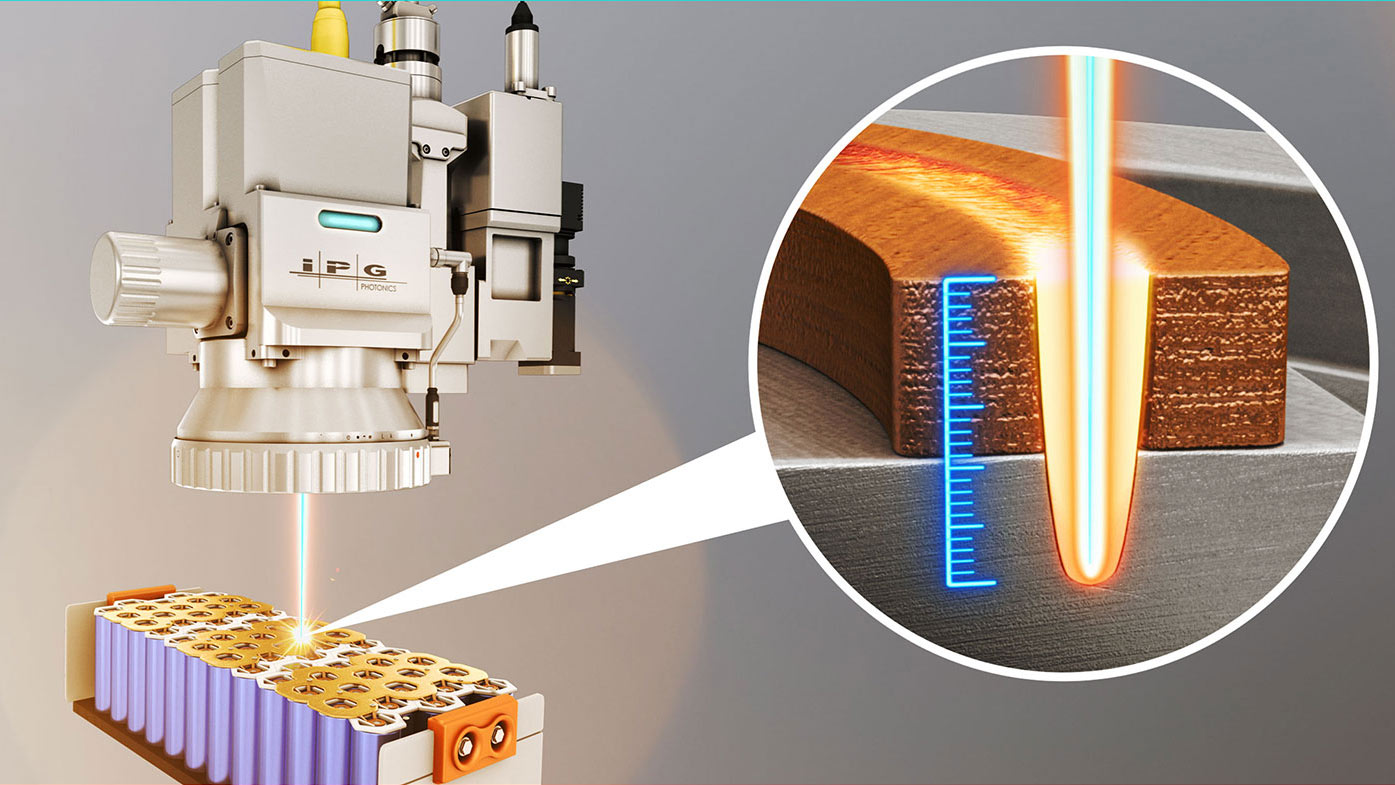

Inline Coherent Imaging (ICI): inline coherent imaging — a type of Optical Coherence Tomography (OCT) — is a proven method of in situ direct laser weld measurement (as opposed to laser weld monitoring).

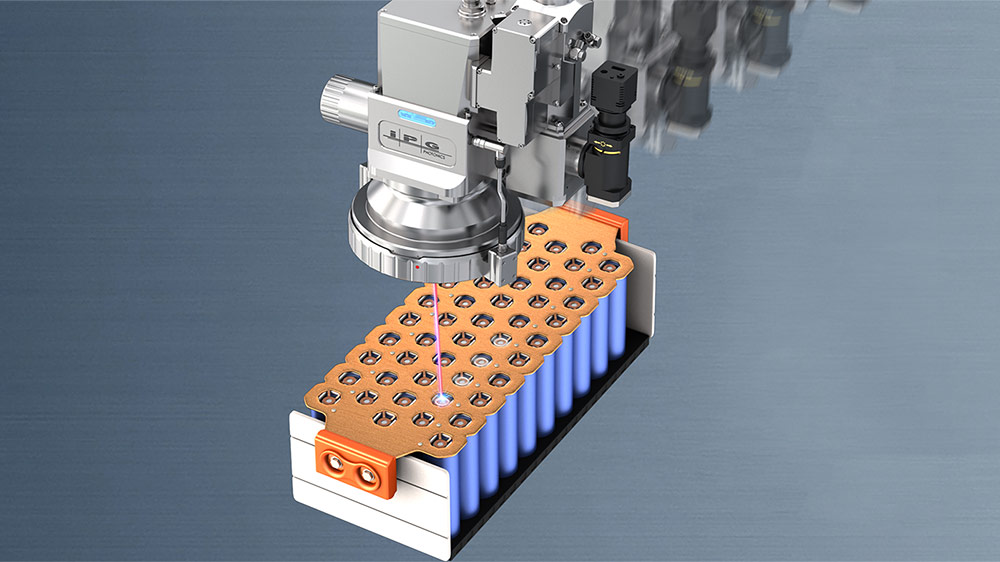

IPG LDD systems use a patented version of ICI built for and used in a broad range of laser welding applications. LDD systems utilize a low power laser beam fired alongside the welding beam to directly measure critical weld geometries like weld depth. Despite operating in real-time alongside the welding process, LDD provides extremely accurate (within a few microns) measurements of every weld.

The Benefits of Laser Weld Measurement vs. Monitoring

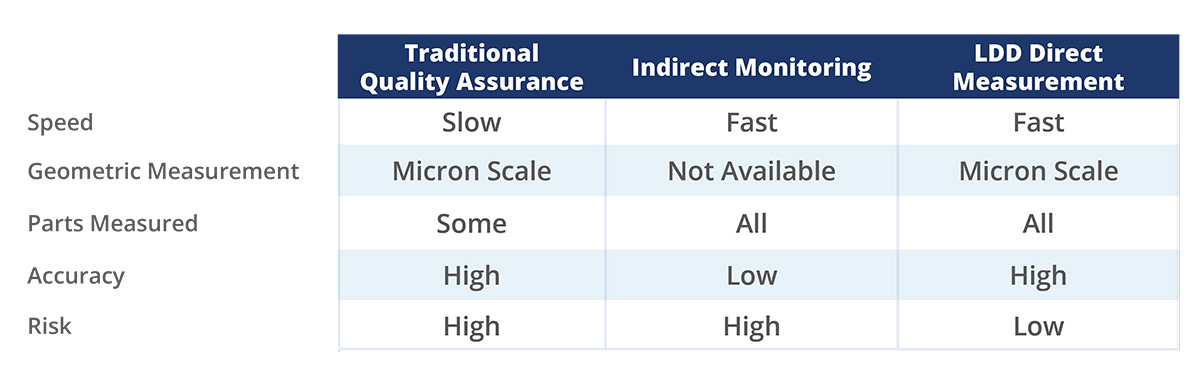

Laser weld measurement is a type of laser weld monitoring. However, not all laser weld monitoring can be considered measurement, at least in regard to actual weld geometry.

Ultimately, any approach that does not directly measure the geometry of every weld forces manufacturers to make compromises on throughput, efficiency, or risk tolerance.

For example, monitoring techniques that rely on indicators like weld plume can provide a semi-accurate estimate of weld depth. But these estimates are far enough from perfect that a safety buffer becomes necessary. While the monitoring data may suggest that a weld is good, if it close enough to the edges of acceptability, it is safer to rework or scrap that part. Depending on the risk tolerance of the manufacturer, hundreds of parts per day may be unnecessarily lost.

The aim of laser weld measurement is to dramatically reduce that safety buffer. By providing a micron-level direct measurement of the weld, the window of acceptability can widen dramatically while providing peace of mind and historical data on every weld.

Industries That Benefit from Real-Time Laser Weld Measurement

In industries like battery welding, electric vehicles, and medical device manufacturing, safety implications are high and quality assurance is critical. For high-stakes applications, real-time laser weld measurement can not only be the difference in reducing waste and costs but also for increasing safety.

Additionally, consumer electronics such as smartphones, tablets, and laptops that require precision inline inspection can see benefits from laser weld measurement.

With the technology of real-time laser weld measurement constantly advancing, industries that favor strength over speed may be able to benefit as well. For example, industries like shipbuilding, where load-bearing welds have strict quality requirements standards, benefit from the advantages of directly measuring the depth of deep-penetrating laser welds.

Getting Started with a Laser Solution

IPG real-time laser weld measurement helps manufacturers catch weld defects, avoid product recalls, and reduce unnecessary scrap and rework.

Getting started is easy – send us some sample parts, visit one of our global application labs, or just tell us about your application.