Prepare to be amazed!

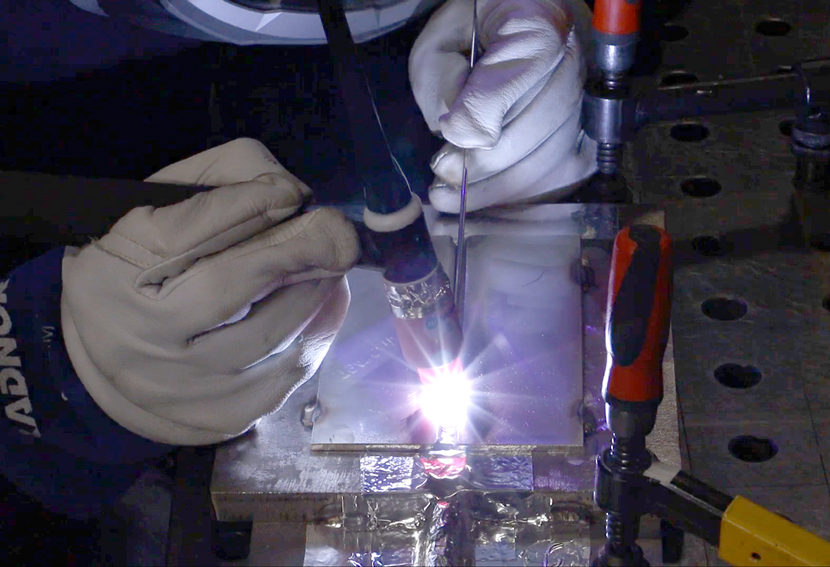

Made in the US to ensure full control over product quality, LightWELD handheld laser welding and cleaning systems are designed to revolutionize your weld quality and productivity. LightWELD laser welding is fast, easy to learn, and produces high quality, consistent results across a wide range of materials and thicknesses. Pre-weld and post-weld laser cleaning functionality optimizes weld quality while increasing productivity.