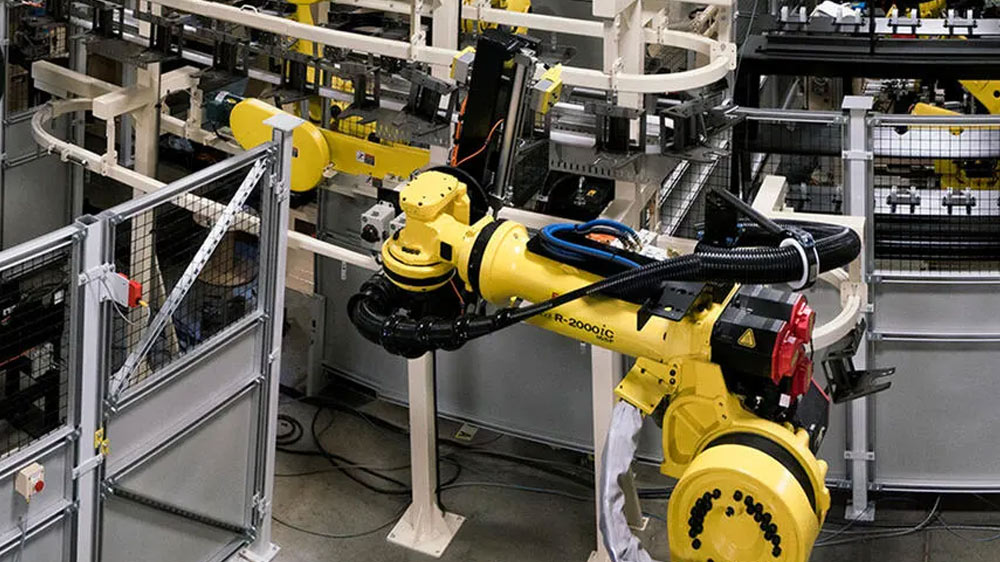

A robotic welding system can boost productivity, improve weld quality, and reduce manufacturing costs. But the benefits achieved in practice depend on how effectively a system is used over time.

There are two primary ways to maximize automation ROI. The first is to minimize system downtime and the second is to optimize operational efficiency.

Here are the 11 “best practices” for achieving these goals as recommended by our own robotics and automation experts at IPG.

#1. Perform regular preventative & predictive maintenance

Using preventative and predictive maintenance to identify and solve problems before they occur is the surest way to avoid production interruptions. In a lot of cases, preventative and predictive maintenance also help maintain the highest level of product quality.

Key items that should be on your preventative maintenance checklist include:

- Scheduled checks of torches, optics, cables, consumables, and coolant systems.

- The use of predictive tools (IoT sensors, thermal monitoring, vibration analysis, and laser power feedback) to catch nascent failures.

- Tracking of consumable lifespans (contact tips, nozzles, optics) to ensure replacement before a failure or significant degradation in performance occurs.

#2. Actively manage consumables & spare parts inventories

It seems simple, but neglecting to stock a proper inventory of spare parts is a surprisingly common mistake. Spare parts are necessary to keep equipment operational and make any needed repairs. Having the right part already on hand has the potential to dramatically reduce maintenance or repair downtime.

To optimize spare part accessibility:

- Keep standardized consumables (contact tips, nozzles, lenses, protective windows, wire liners) available and ideally near the equipment.

- Minimize variation in consumables across cells to reduce confusion and the chance of using the wrong part.

- Consider vendor-managed inventory (VMI) to ensure critical parts are always available.

#3. Do programming & simulation offline

Setting up a new job and programming robotic weld paths can take time. If this task is performed on a production system, it can cause unnecessary downtime and interrupt output. Offline programming (OLP) and simulation tools enable you to shift that work to a virtual environment. This saves time and reduces the chance of errors.

To get the greatest benefit from offline programming:

- Validate paths, cycle times, and reach envelopes before deployment.

- Use simulation to identify potential collisions, torch angle issues, or fixture interferences before they happen.

- Create programs offline to eliminate the need for manual teach-ins.

#4. Thoroughly train operators & maintenance personnel

Well-trained operators consistently get the highest efficiency and best results from a robotic welding system. Knowledgeable maintenance personnel prevent small issues from escalating into major downtime events and respond more quickly when problems do occur.

To strengthen your team’s skills and responsiveness:

- Train operators to quickly identify and resolve the most common issues, such as wire birdnesting, optical contamination, or system reset procedures.

- Crosstrain maintenance and production staff to ensure consistent support and coverage across shifts.

- Post clear, visual SOPs at each cell. This should help to minimize troubleshooting time and standardize best practices for consistent quality.

#5. Implement real-time monitoring & alerts

Real-time system status and weld performance monitoring is a valuable adjunct to predictive maintenance. It enables your team spot to anomalies early and prevents small issues from growing into extended downtime.

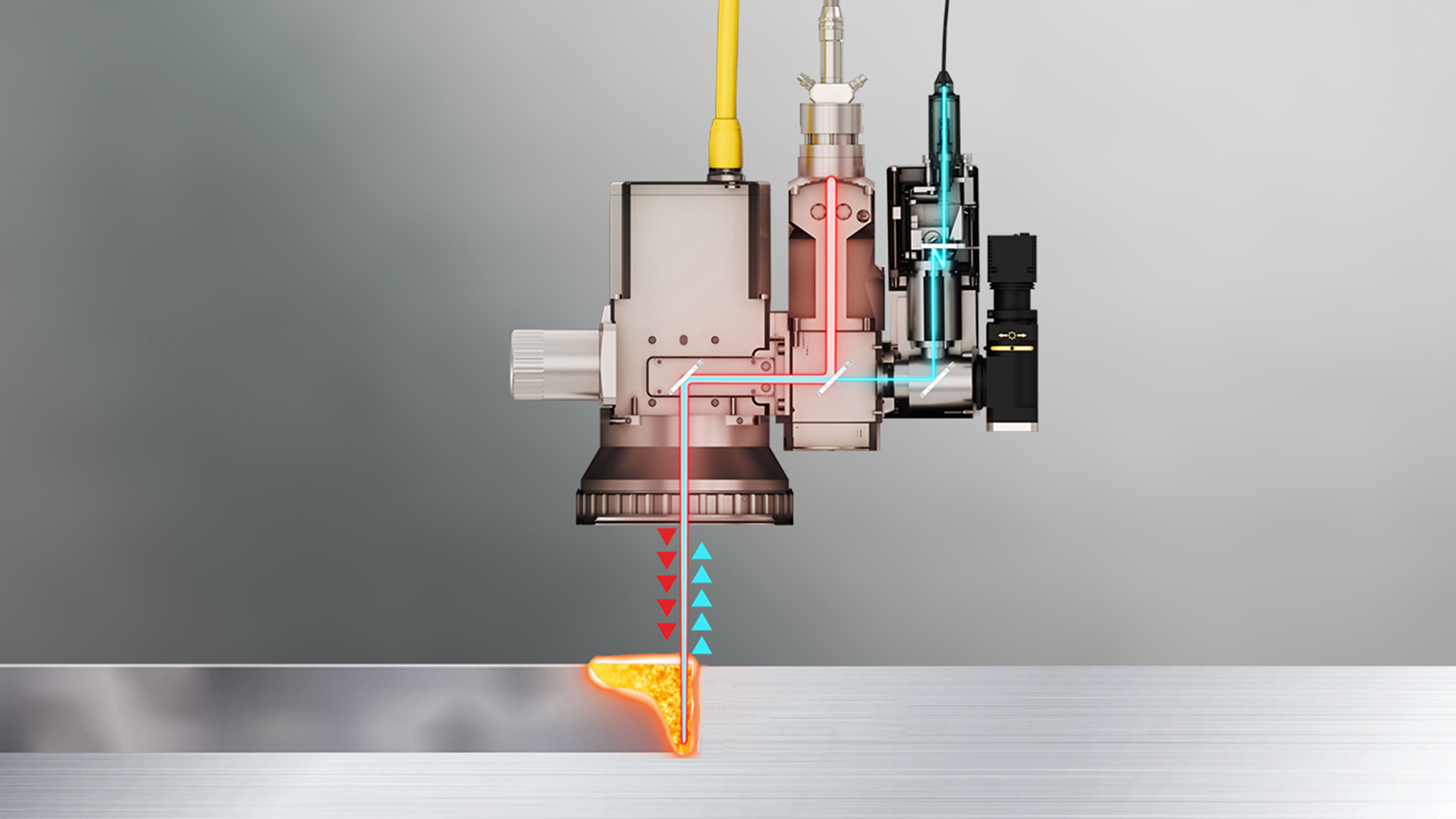

For example, there are a variety of laser weld monitoring tools and technologies that offer significant improvements over QA methods like destructive testing. Methods like real-time direct weld measurement provide highly accurate geometric data that can be used to predict defective welds before they happen.

To get the most from real-time monitoring:

- Implement dashboards for robot status, weld parameters, and fault tracking.

- Send automatic alerts (text/email) when thresholds are exceeded or faults occur.

- Log downtime events to analyze trends, identify root causes, and implement countermeasures. This data can also help drive continuous improvement.

#6. Maintain proper wire feeding

Wire feeding issues are some of the most common causes of downtime in robotic welding. Even small inconsistencies can reduce weld quality and cause unnecessary stoppages or costly rework.

To ensure and maintain proper wire feeding:

- Verify that liners are the correct length and don’t create drag during robot articulation.

- Match drive rolls and tension settings to the wire type to prevent slipping or deformation.

- Prioritize stable wire feeding – it directly translates into stable production.

#7. Maintain precise joint fit-up & gap control

Even the best robotic welding system cannot always compensate for poorly aligned or inconsistently presented parts. Poor fixturing or variations in part placement both lead to weld defects, rework, and unplanned downtime. It is well worth investing in robust, repeatable fixturing to keep production stable and weld quality high.

- Use precision fixturing with “poka-yoke” features. These include built-in guides that guarantee proper part orientation, pin-and-slot locators for consistent placement, and automated clamps that apply uniform clamping force.

- Design fixtures to be insensitive to variations in operator loading or part tolerances.

- Ensure precise joint fit-up and gap control to prevent weld gaps and failures and to avoid stoppages.

#8. Design for quick-change serviceability

The use of quick-change components makes routine service faster and easier. They also minimize mean time to repair (MTTR) when unexpected issues occur. Designing for serviceability is designing for uptime.

To maximize serviceability:

- Equip systems with quick-change torch mounts, cartridge-style optics, and modular consumables.

- Streamline routine maintenance so technicians can complete tasks quickly and consistently.

- Reduce MTTR by design, ensuring that repairs require minimal tools, time, and disruption.

#9. Supply the robot with high-quality parts

A robotic welding system can’t entirely compensate for low quality parts. Poorly made or inconsistent parts inevitably lead to weld defects, rework, and unnecessary downtime. While technologies like vision systems, seam tracking, and robust fixturing can help, they add cost and complexity.

This is especially true for laser welding. While laser welding is a precise process that creates high-quality joints, it is sometimes less tolerant of wide tolerances and part quality variations than other joining methods. Laser welding offers the most benefits when parts, assemblies, and upstream processes are designed with it in mind.

To consistently produce parts that support high-quality robotic welding:

- Design and manufacture parts with tight tolerances, consistent materials, and proper joint preparation.

- Verify part consistency before units reach the cell. This will reduce the need for rework and process adjustments.

- Minimize reliance on compensating technologies, using them as safeguards rather than substitutes for poor part quality.

#10. Accurately set up & configure your robot

Accurate setup is essential for keeping a robotic welding system both productive and reliable. Errors in tool center point (TCP), mastering, or torch/optics integrity can lead to misalignment, poor weld quality, or unplanned downtime. Regular verification and calibration keep the robot repeatable and prevent issues before they disrupt production.

To optimize robot setup and configuration:

- Verify correct TCP, mastering, and torch/optics integrity during setup and after maintenance.

- Use alignment and position checks to confirm repeatability. This includes robot wrist verification tools, end of arm tooling (laser or torch) alignment, and laser alignment coupons.

- Maintain consistent calibration to reduce variability and eliminate downtime caused by setup errors.

#11. Actively control the production environment

The operating environment has a direct impact on robotic welding reliability. Dust, fumes, and temperature fluctuations can degrade equipment performance and shorten component life – especially in the case of laser welding optics. Proactive environmental controls protect sensitive systems, reduce contamination, and keep production running smoothly.

To minimize environmental impacts:

- Use effective fume extraction and airflow management to minimize contamination.

- Protect lenses and other optics with appropriate covers and perform regular cleaning.

- Stabilize the environment with active temperature and humidity control to maximize process consistency and prevent heat-related interruptions.

Think of robotic welding as an ongoing process of optimization, not just a one-time investment. By taking the steps outlined here, you can minimize downtime, maximize efficiency, and consistently produce high-quality parts. This will help you to realize the full return on your automation investment and protect it well into the future.

Getting Started with a Robotic Solution

Considering a robotic welding solution? Getting started is easy – send us some sample parts, visit one of our global application centers, or just tell us about your application.