One of the most fundamental equipment decisions when automating a laser process is whether to use a robotic or a gantry-based motion platform. Each offers distinct advantages, and neither is universally better.

The right choice depends on several factors. These include the nature of the process itself, the required throughput, the allowable cost, and various integration constraints.

Here we’ll explain how robotic and gantry laser systems work and explore their key tradeoffs. This will help you make the best choice for your own application.

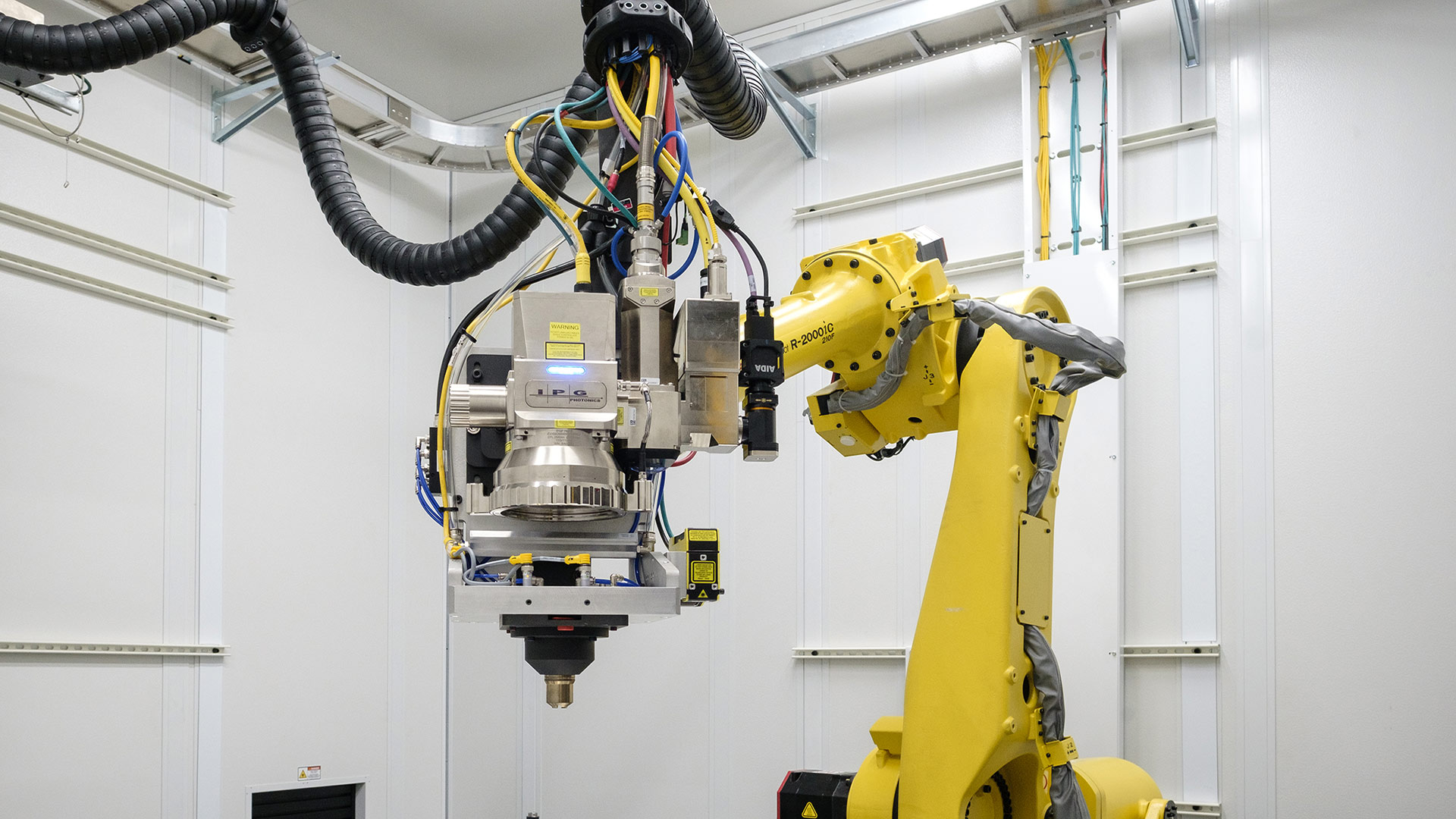

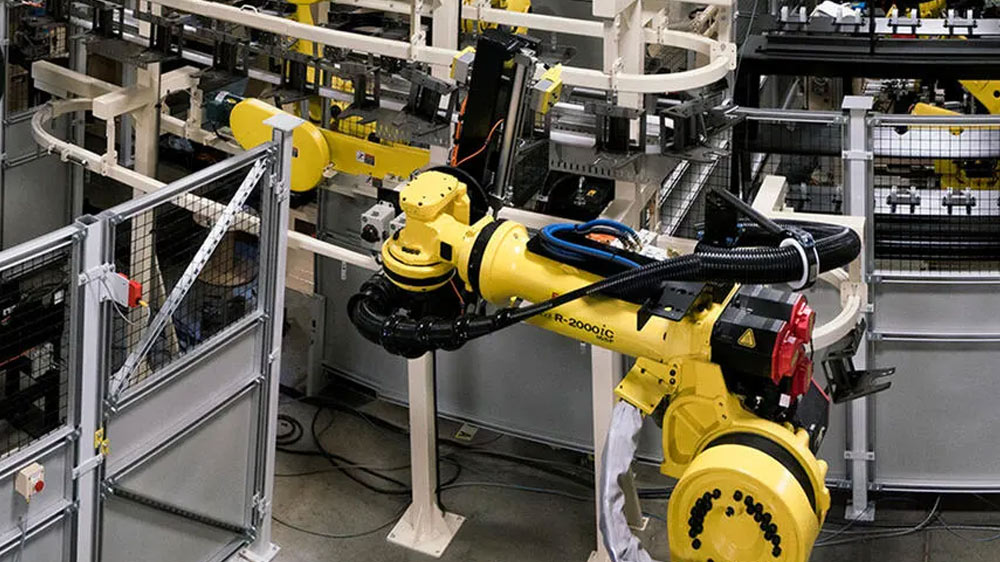

Robotic Laser Systems

This form of automation uses a multi-axis industrial robotic arm to move a laser processing head in relation to parts. The robot arm follows a programmed path, and its ability to move the head in up to six degrees of freedom enables it to perform laser processing in a wide range of positions and orientations with respect to the part.

The laser itself may be mounted at the end of the robotic arm, or it could be delivered there by fiber optics from a stationary source. The beam delivery optics incorporated into the end-of-arm tooling (EOAT) can include fixed-focus optics, wobble heads, or scan heads depending on the process.

In some systems, parts are mounted to tooling secured to a fixed base or rotary table. Alternately, the robotic arm may be positioned next to a conveyor system for inline production. In this case, arm motion can be coordinated with the part, and auxiliary positioners – such as a tilt or rotary axis – can be used to increase access or maintain consistent beam orientation.

Gantry (Cartesian Motion) Laser Systems

Gantry laser systems use a motion platform to move either the laser beam or the part along linear X, Y, and (sometimes) Z axes. The motion follows a programmed path which can range from straight lines to curves. But the angle of the beam usually remains fixed and is typically perpendicular to the part surface.

For most gantry systems, the laser is located off the gantry and delivered via fiber optic cables. The beam delivery optics on the gantry can include fixed-focus lenses, wobble heads, or scan heads depending on the process. The use of a scan head enables on-the-fly (OTF) processing capabilities that are particularly useful for high-speed on-the-fly laser welding.

Gantry systems are often built on steel or granite work platforms. This provides a highly stable foundation to enable precision work.

Decision Factors

The different methods that robotic and gantry systems use to move the laser beam result in distinct characteristics in terms of capabilities, cost, and practical implementation. While some applications might be equally well serviced by either, in most cases one technology provides a clear-cut advantage. That determination can usually be made by considering the following factors:

- Flexibility

- Precision

- Speed

- Integration Considerations

- Programming

- Cost

Let’s take a closer look at each of these.

Flexibility

Robotic laser systems offer far greater flexibility in motion than gantry systems. A robotic arm can approach parts from virtually any angle, making it ideal for processing complex, three-dimensional geometries or features located on multiple faces of a part. This ability is particularly valuable in applications like automotive assembly, where the same robot may need to process parts with irregular or non-planar surfaces.

With more limited degrees of freedom in terms of motion, gantry systems are generally best suited to processing on flat surfaces. Additional motion stages can be added to allow vertical or rotational motion, but this will never match the range of motion achievable with a robotic arm.

When parts have complex, 3D geometries, or if the same cell must process a variety of part types or orientations, robotic systems tend to be the better choice.

Precision

Gantry laser systems generally offer superior precision and repeatability compared to robotic tools. Their rigid linear motion stages, low moving mass, and simplified kinematics allow for highly accurate path control. This is further enhanced when the gantry and part are mounted together on a highly stable platform.

In contrast, robotic systems introduce more mechanical variation due to joint deflection, backlash, and calibration drift. This substantially lowers their accuracy and repeatability compared to gantry systems.

The accuracy of robotic systems can be enhanced with additional vision systems or calibration tools. However, this slows their movement down and also adds cost and complexity.

While robotic laser systems offer enough precision for many laser cutting, welding, and cleaning tasks, their limited accuracy can reduce the process window. This makes generally them unsuitable for the most demanding electronics, medical devices, or battery fabrication applications.

Speed

The relative speed or takt time of robotic and gantry systems is highly application dependent. But gantry systems typically outperform robots in tasks requiring high-speed, repetitive motion.

Gantry platforms can move quickly along straight and curved paths while maintaining precise control over velocity. This makes them ideal for marking, cutting, or welding along continuous contours. The use of OTF processing can further increase their throughput.

In contrast, robotic systems excel at navigating complex 3D or multi-plane paths. But they are slower in start-stop operations and less stable during rapid direction changes. Their larger moving mass and multiple joints reduce acceleration and deceleration rates compared to gantry systems.

If the application requires smooth, continuous motion over flat parts, gantries offer better cycle times. But for multi-face access or 3D contour following, robots may be faster overall by eliminating the need for part repositioning or secondary fixturing.

Integration Considerations

The configuration of robotic laser systems inherently provides greater flexibility for integration into complex or space-constrained production environments. A robotic tool can be positioned next to a conveyor, placed within a compact work cell, or configured to service multiple stations. This makes them great for applications where part flow, tooling layout, or process variety requires adaptive motion.

Gantry systems tend to require a larger dedicated footprint due to their rigid structural frames and overhead motion system. Part access is generally vertical, which can limit how the system is integrated with upstream or downstream processes. For simple standalone operations, however, gantries are often easier to implement.

Programming

The programming environments used for laser automation systems vary by manufacturer, so it’s difficult to make universally true statements. However, in general, gantry systems are easier to program and control, especially for users already familiar with CNC equipment.

Most gantry platforms use standard G-code or CAD-to-path software. These generate toolpaths in absolute, linear coordinates within a fixed machine reference frame.

This means the programmed path corresponds directly to the part’s physical location. This makes programming fairly straightforward and intuitive.

Robotic systems, by contrast, require more complex path planning. This is particularly true in 3D applications, or when the tool must approach from varying angles.

Programming robotic systems typically incorporates 3D models. Motion must be defined relative to both the part and the robot’s kinematic structure.

This involves mathematical transformations to resolve joint angles, tool orientation, reach, and collision avoidance. As a result, robotic systems demand more advanced software tools and a higher level of training.

Fortunately, the risk and complexity of robotic laser welding projects can be reduced with virtual engineering and simulation tools and techniques.

Compared to other robotic laser systems, cobotic laser systems are designed to be significantly easier to program and operate. Since part programming is comparatively simple, laser-based cobots do not require staff with previous robotic experience to operate them.

Cost

Gantry systems are generally more cost-effective for simple, flat-part processing where a high degree of precision is required. Their mechanical simplicity and widespread use in automation make them comparatively affordable for high-volume production.

Robotic laser systems may involve higher initial investment. This is especially true for multi-axis robots, and when safety enclosures and programming tools are also factored into the cost.

Robotic laser systems will usually deliver better value in flexible or multipurpose applications. It’s even possible to use a tool changer to swap out the processing head with a robotic arm enabling a single cell to cut, weld, or perform other tasks. This can reduce the need for additional equipment and improve ROI in a variety of production environments.

Getting Started with a Laser Solution

Ultimately, choosing the right approach to system motion depends on your part mix, performance requirements, and integration constraints.

At IPG Photonics, we build both robotic and gantry laser systems. Getting started with a laser system or solutions is easy – send us some sample parts, visit one of our global application centers, or just tell us about your application.