The decision to automate a process is a major one for many manufacturers, small and large. But this choice is about much more than just technical capabilities and initial capital cost. Rather, it’s a strategic commitment that shapes how you make your products, how flexible your production line will be, and how you’ll compete in your market.

Once you choose an automation path, you are – to a certain extent – buying into an entire set of capabilities, constraints, and future options. The right decision can improve quality, boost throughput, and position your business for growth.

The wrong choice can lock you into a system that’s difficult or expensive to upgrade when your needs change. Alternatively, you may find you’ve overspent for capabilities you’ll never use.

When it comes to laser systems, commercially available products generally fall into two broad categories – pre-configured systems and custom systems. While these are really just two ends of the spectrum, this distinction is useful for outlining key decision-making criteria.

This article is intended to help you make the right decision for your business.

What is a Pre-Configured Laser System?

A pre-configured laser system is usually intended to offer a lower entry price point and is designed to perform a defined, limited range of tasks. These systems target manufacturers who want to automate common laser processes – such as welding, cleaning, or cutting – without taking on the time and cost of custom engineering.

Pre-configured systems are especially attractive to small and mid-sized manufacturers, or to larger operations looking to add capacity quickly for standard, repeatable processes. The appeal is in their simplicity. They’re built to be reliable, easy to install, and fast to deploy.

Pre-configured systems are usually self-contained units housed in a Class 1 laser-safe enclosure, complete with access doors, interlocks, or light curtains to ensure operator safety. They’re generally designed to function as stand-alone work cells or workstations rather than components of a fully automated production line.

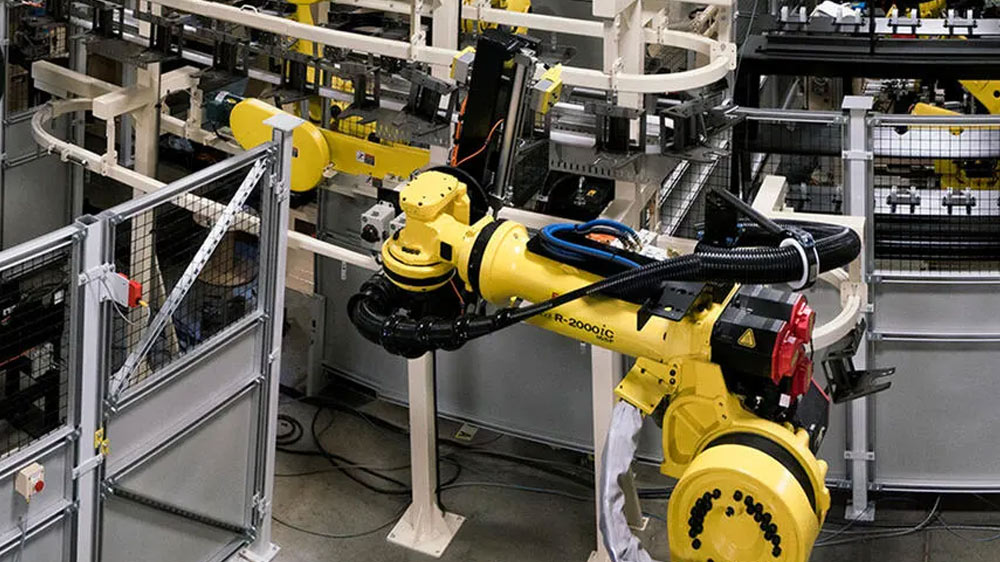

Depending on the target application and part size, a pre-configured system can utilize gantry (cartesian) motion or a robotic arm. Gantry systems are typically built on a work platform made from steel or granite, providing a stable foundation for precise operations. Robotic systems most commonly incorporate a 6-axis industrial robot.

It’s not uncommon for suppliers to offer their pre-configured systems with options. These may include various laser sources, beam delivery optics, and maybe even vision or process monitoring systems.

Various part holding and mounting interfaces, like trays or rotatory mounts are also frequently available, especially for marking systems. Interfaces for semi-automated loading or unloading, like conveyor loading or turntables, are sometimes available.

A key characteristic of pre-configured laser systems is simplicity and ease-of-use. The human-machine interface (HMI) usually provides a clean, menu-driven control environment with access limited to preset programs or recipe parameters. This enables use by shop-floor personnel with minimal specialized training. For the process engineer, creating new tasks is similarly simplified and accessible for those with limited programming skills.

What is a Custom Laser System?

A custom laser system is designed from the ground up to meet a specific set of production requirements that fall outside the capabilities of pre-configured systems. Each custom system is, by definition, essentially unique.

However, custom laser systems tend to consist of several common – and possibly even standardized – building blocks. These can include:

- Automated material handling

- Part fixturing and tooling

- Part motion and positioning

- Laser source and beam delivery

- Vision, sensing, and process monitoring

- Controller and associated software

- Communications module (to interface with the MES, PLC or other factory automation control systems)

- Safety and enclosure

These elements can be combined in just about any manner, and high levels of complexity and sophistication are possible. Motion systems might include multiple robot arms, gantries, linear stages, or rotary tables. Sometimes these work independently to process parts in parallel. Sometimes they coordinate to achieve the necessary reach, precision, and speed.

In terms of the user experience (UX), custom systems typically feature tailored HMIs that provide deeper control and monitoring capabilities. Operators and process engineers may have access to advanced diagnostic tools, customizable process parameters, and interfaces that support recipe management or high-mix production. Typically, a fair degree of programming and automation expertise is usually required to run these tools.

While custom laser systems can be standalone work cells, they are often designed for integration into facility-wide automation systems and production lines. They may provide connectivity to PLC networks, MES platforms, and SCADA systems using standard industrial protocols like EtherNet/IP, Profinet, or OPC UA.

Choosing Between a Pre-Configured & Custom Laser System

Choosing the right approach to laser automation involves considering and balancing many factors. Some are obvious, such as capital and operating costs and available floor space. Some are less obvious, like the quality of vendor support and upgradeability.

With so many variables, decision making can be overwhelming. To streamline this process, it helps to identify and focus on those core issues that are most likely to determine success or failure. In terms of just system functionality, we’ve found that these seven factors are typically the most critical.

Application Fit

This is the foundation and starting point of the decision-making process. It’s first necessary to define your process and then determine if a laser can deliver the best results.

To make this assessment, you must understand what the laser brings to the table – whether it’s speed, precision, reduced heat input, or lower operating costs – and decide how success will be measured. If there’s no clear definition of what the task is and what constitutes success, then there’s little chance of achieving it.

This is where applications development services from laser automation partners can be helpful. Ideally, they should have the equipment and experience to identify, test, and optimize your laser process.

Part Size

This might seem like a mundane consideration, but it plays a critical role. Laser systems are constrained by their working envelope.

Pre-configured systems are engineered around typical part dimensions for specific industries – small, precise components in medical devices, or mid-sized assemblies for general industrial use, for example. When parts fall outside these norms – whether they’re larger or unusually shaped – it often drives the need for a custom or heavily modified system.

Throughput Requirements

Throughput capabilities are an area where pre-configured and custom solutions are commonly differentiated. Given that productivity is a primary goal of automation, this is often the deciding factor.

Pre-configured systems are usually designed as single station work cells or workstations. As a result, they’re typically best for low to medium throughput needs. Part loading and unloading, especially if it’s being performed manually, is often the rate limiting factor for a pre-configured system.

For example, technologies like on-the-fly welding can achieve welding speeds of more than 1000 welds per minute. This can increase throughput in a standalone workstation like the EV-Cube, but conveyance and integration into a production line can improve throughput further.

By contrast, the speed a custom laser system can attain is often only limited by cost investment, space restrictions, or non-laser bottlenecks. Custom systems can incorporate multiple laser sources or optics, several kinds of system motion, or non-laser processes running in parallel to achieve very high throughput.

Depending on your requirements, it may still be more cost effective to install multiple standard systems rather than investing in a larger, custom-built line.

Some pre-configured systems support automated part loading options, or the ability to integrate with conveyor belts. This can up throughput by minimizing system idle time while parts are being loaded or unloaded.

Tooling

Diving further into part loading, it’s also worth examining how the part is fixtured and presented to the laser. Standard systems typically have a limited range of part holding options. These might include fixed clamps, locating pins, manual or pneumatic chucks (for round parts), and v-blocks. This may limit the system’s ability to execute complex weld paths or work with 3D shaped parts that require processing from several angles.

If parts require complex positioning, dynamic fixturing, or interaction with external systems, the tooling must be designed accordingly. Of course, this can be obtained with a custom robotic system. But it’s also where the capabilities of a pre-configured tool may be extended, assuming the manufacturer has the capabilities and willingness to do so.

Tolerances and Quality

While tooling plays an important role in determining process accuracy and repeatability, it can be augmented with various sensors, and especially vision systems. These can help the system to better accommodate part-to-part variations or compensate for limitations in the positional consistency of the tooling.

Some pre-configured systems may include vision systems and process monitoring as standard options. For example, welding configurations of the IPG LaserCell platform are available with LDD Real-Time Laser Weld Measurement systems for inline weld monitoring.

However, it’s possible that the combination of part complexity and tolerance requirements can create requirements that exceed what a pre-configured system can accommodate. This pushes the solution toward a custom or semi-custom design.

Laser Power

Standard laser systems are built to accommodate certain laser power ranges. This is usually dictated by the tool’s optics, safety systems, cooling needs, and perhaps even power requirements.

However, increased process speed requirements or thicker materials may necessitate a higher power laser.

Some of these limitations aren’t easy to upgrade or expand. So, if an application absolutely demands higher laser power than what a standard system can deliver, that can force the decision to build a custom laser solution.

Operator Interaction

In addition to system functionality another important consideration is how easily it can be programmed and operated. This is another area where pre-configured and custom systems tend to diverge significantly.

Pre-configured systems are built for predictable, straightforward interaction, and usually support a limited selection of operations. Programming of new tasks is often simplified and sometimes even reduced to just drag-and-drop functionality, such as in a laser welding cobot system.

All this relaxes the training requirements for both operators and process engineers. It also means that systems can usually be up and running in production almost immediately after installation.

Custom robotic laser systems may include a simplified user interface for operators. But underneath that is usually a much more sophisticated software environment.

The benefit of that sophistication is that they have virtually unlimited capabilities. This often includes the ability to integrate with other factory automation systems.

But this also means they are typically more complex and harder to program, requiring greater expertise to support. It’s not uncommon for it to take longer to bring a new system or process online, especially when it involves extensive interaction with external systems.

Other Considerations

As mentioned previously, purchasing a laser system is not really a binary choice. With some suppliers, it’s possible to start with a pre-configured system and modify it with options until it essentially becomes a custom system. With others, pre-configured systems are rigid and optimized for a narrow range of tasks.

Pre-configured robotic laser systems typically cost less than fully custom tools and can usually be delivered faster by the manufacturer. Furthermore, installing a pre-configured system will likely involve less of a learning curve since the manufacturer already has substantial experience with its use in a variety of production settings.

Modifying a standard system to expand system functionality also usually incurs a smaller incremental increase in cost than obtaining that same capability through a totally custom system. But this isn’t universally true. Pre-configured systems have limitations which can make performing extensive modifications more costly than starting from scratch.

There are logistical and financial issues, too. Modifying a pre-configured system that is already in production use takes that tool offline. That downtime has an impact. But the costs for making that modification may come out of operating expenses, while a new system purchase is invariably a capital expense.

Finally, remember that any specific vendor might only offer a limited product range. This can incentivize them to steer you towards a solution from their existing products or capabilities. Unfortunately, this product may not offer the optimum fit for your application.

Getting Started with Laser Automation

Thanks to our unique vertical integration, IPG offers everything from laser components and technologies to pre-configured systems, modular platforms, and custom production lines. As a partner for all things laser automation, we don’t push you towards a particular product or approach.

Getting started is easy – send us some sample parts, visit one of our global application labs, or just tell us about your application.