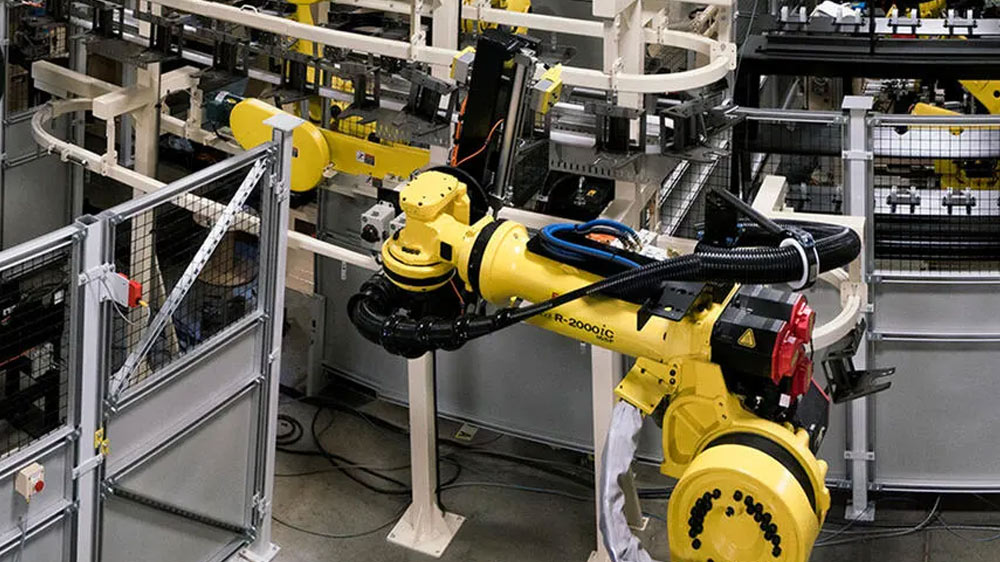

Manufacturers that rely on arc welding in production face persistent challenges including a shortage of skilled labor, inconsistent weld quality, low yields, and insufficient throughput. Automating the welding process offers a powerful way to overcome these challenges. Robotic automation can boost productivity, improve repeatability, and reduce long-term operating costs.

But only if it’s done right.

Actually experiencing the full benefits of robotic welding requires more than simply installing a system. Success starts by selecting the right welding process and then optimizing parts and fixtures for automation. Poor fit-up, inaccessible joints, or overly complex programming can all undermine the benefits of automation.

This article explores how to identify which arc welding processes best lend themselves to automation and then reviews best practices in system design and implementation.

Robotic Arc Welding Advantages

Robotic arc welding offers a powerful solution to many of the limitations found in manual welding. One of its biggest advantages is consistency. Robots don’t get tired, distracted, or vary significantly from one weld to the next. Once programmed, they can deliver repeatable, high-quality welds hour after hour, shift after shift. This translates into higher precision, fewer defects, reduced rework, and better overall product quality.

Production speed and throughput are also dramatically improved. A robotic system can often complete a weld in a fraction of the time it takes a human welder – even a highly skilled one. And this is especially true in high-volume applications.

Safety is another important factor. When properly deployed in the production environment, a robotic system separates workers from heat, fumes, and arc flash. It allows skilled welders to transition into supervisory or programming roles where their expertise can add more value.

And while the initial investment in automation can be significant, the long-term cost savings – from reduced scrap, lower labor costs, and improved uptime – provide a strong return on investment. This is precisely why companies across numerous industries are leveraging robotic arc welding to stay competitive, improve quality, and scale production.

Robotic Process Compatibility

Not all arc welding processes are equally suited for robotic automation. But several stand out for their compatibility and effectiveness.

Gas Metal Arc Welding (GMAW/MIG) is by far the most commonly used method in robotic applications. This is because it’s relatively straightforward to automate, delivers high deposition rates, and is applicable to a range of materials and thicknesses. Robotic MIG welding is particularly well-suited for high-speed, repetitive welds and often reduces the need for extensive post-weld cleanup.

Gas Tungsten Arc Welding (GTAW/TIG) offers high precision and clean welds. But it is less common in robotic systems because it requires more complex control and is a slower process. Robotic TIG welding is mostly reserved for applications where weld quality and aesthetics are critical.

Flux-Cored Arc Welding (FCAW) and Submerged Arc Welding (SAW) are more specialized methods. They are mostly used in heavy fabrication industries like shipbuilding or structural steel, where thick materials and deep penetration are required. Robotic integration brings consistency and improved throughput to these processes which are typically difficult to scale up with manual welding.

Design Considerations for Robotic Efficiency

To get the most from robotic arc welding, it’s essential to design both parts and processes with automation in mind. This involves thinking through the entire workflow – from how parts are loaded to how they move through the system. When these elements are aligned, robotic arc welding becomes faster, more reliable, and easier to scale.

In terms of the parts themselves, one of the most critical factors is consistency. Robots excel at repeatability, but they rely on predictable inputs. Variations in part dimensions, joint fit-up, or weld locations can result in poor welds or system faults. Consistent fixturing, proper tolerancing, and precision in part manufacturing all contribute to reliable robot performance.

Joint accessibility is another key factor. Robots need clear and unobstructed paths to reach weld seams. Complex geometries or tight spaces can limit the robot’s ability to orient the torch properly. Plus, tricky geometries increase programming difficulty and can require repositioning systems. Planning weld access during the design phase avoids changes and production delays later on.

Integrating material handling systems – such as positioners, turntables, or conveyors – can further enhance efficiency by reducing manual involvement in the process. They can be used to move or orient the part so that the weld joint is always presented to the robot in a consistent, accessible, and ideal orientation. This ensures that welding is performed with best torch angles. And, if parts can be loaded/unloaded while another is being actively welded, then cycle times are reduced.

Key Technologies That Maximize Robotic Performance

Modern robotic arc welding systems can be much more than just mechanical arms that blindly execute a pre-programmed series of movements. They can incorporate various advanced technologies to significantly improve weld quality, efficiency, and adaptability with minimal operator intervention.

One of the most impactful technologies is seam tracking. This involves using sensors to detect and follow the actual (rather than idealized) path of a weld joint in real time. This allows the robot to adjust for part variations and maintain proper torch alignment throughout the weld.

Touch sensing and laser scanning can also enhance joint detection and positioning. These technologies are especially useful for ensuring accurate weld placement when parts aren’t perfectly consistent or fit up isn’t ideal.

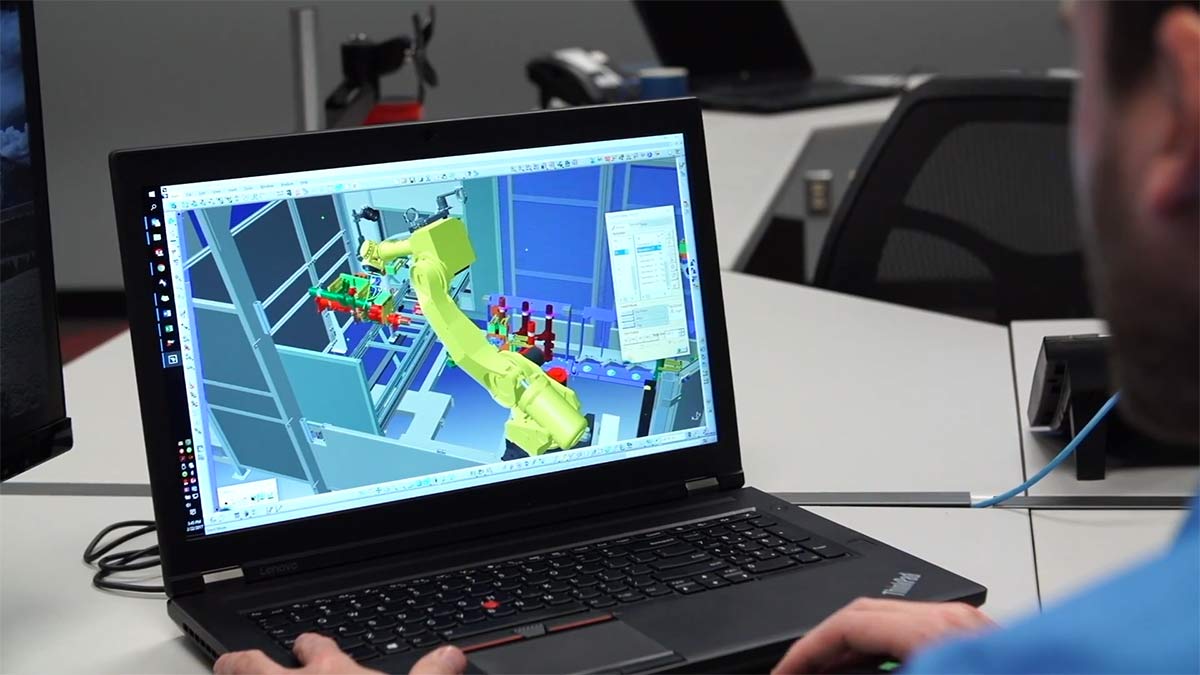

Offline programming and simulation tools are also important tools. These allow engineers to develop and test weld programs virtually, reducing the downtime of production equipment for process development. Simulation also helps identify potential issues before the robot ever touches the part, increasing first-time success rates. It is also particularly useful for optimizing tooling designs.

Some of the most advanced systems are now beginning to incorporate AI and machine learning. These can help with predictive maintenance and weld quality analysis. By collecting data from each weld, the system can detect anomalies, flag potential issues, and even recommend adjustments to improve performance over time.

Mitigating Risk with Pre-Engineered Solutions

The benefits of automating arc welding – including higher productivity, better quality, and long-term savings – are already well-established and widely recognized. So, why do manufacturers sometimes hesitate to implement a robotic welding solution?

Platforms like ArcCell Robotic Arc Welding Systems offer a variety of configurable pre-engineered designs built to address common fabrication requirements.

One increasingly common solution to these challenges is pre-engineered robotic arc welding systems. This type of equipment is particularly well suited for fabricators that need reliable performance but don’t have the internal resources to tackle a complex automation project. Whether the goal is to free up skilled welders, increase throughput, or reduce defects, these solutions deliver a proven road to results which shortens deployment time, reduces engineering risk, and provides a predictable cost structure.

Getting Started with Robotic Arc Welding

Considering a robotic arc welding solution? Getting started is easy – view our configurable range of purpose-built systems and talk to a welding automation expert here.