The need to manufacture small, high-precision metal parts spans different industries, including aerospace, medical devices, electronics, and automotive. Current market trends, such as miniaturization, lightweighting, and the increasing use of rapid prototyping, have only accelerated the demand for miniaturization.

But for many years, no production tool offered the ideal combination of accuracy, speed, and material compatibility for fabricating high-precision small metal parts. Even fewer were sufficiently compact, affordable, and easy to use – critical factors for small to mid-sized manufacturers, and especially those producing parts in limited quantities.

LaserCube Delivers the Edge in Quality and Productivity

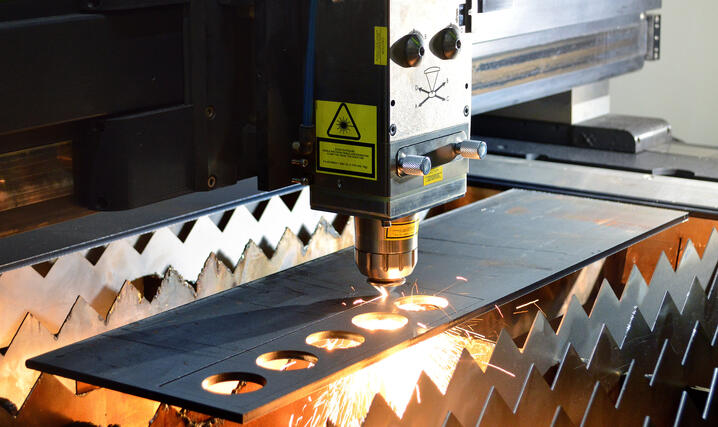

IPG Photonics developed the LaserCube Flatbed Laser Cutting System specifically to fill this market need. This compact fiber laser cutting system is designed and optimized for fast and reliable precision cutting of small parts. The system is equally at home in environments ranging from prototyping to full-scale production.

LaserCube hits the sweet spot for this kind of fabrication owing to several aspects of its design and construction. Some of the most important of these include:

IPG Fiber Lasers

LaserCube utilizes an IPG fiber laser – widely recognized as highly reliable, energy efficient, and optimal for demanding applications. LaserCube supports output powers from 450 W to 6 kW. IPG lasers deliver a combination of critical output parameters, including excellent beam quality and high peak power, that enable high cutting speeds, even in reflective metals.

Linear Motors

The LaserCube motion system utilizes linear AC induction motors and encoders. These eliminate virtually all the moving parts found in traditional motors, such ballscrews, gearboxes, rack and pinion assemblies, and belt drives making them essentially maintenance and wear free. The system’s linear motors deliver also superior accuracy and repeatability. Together, this allows LaserCube to achieve a cutting accuracy of ±25 µm and a repeatability of <10 µm at cutting speeds of up to 1000 mm/s.

Granite Base

High precision and accuracy can only be achieved on a stable platform. That’s why LaserCube is built on a natural granite base. Granite provides superior vibration damping, structural stiffness, and thermal stability ensuring precise and repeatable laser cutting to a degree that can’t be matched by other platform materials like steel or polymer cast concrete.

Vision System

An optional machine vision system guarantees precise cut placement, no matter how parts are loaded, or even if they have dimensional deviations. LaserCube machine vision references various existing part features, such as printed, etched, punched or marked patterns, to place cuts exactly where they belong in relation to these part geometries.

Software

The LaserCube user interface is both comprehensive and easy to use. The interface provides control of virtually all operational parameters for the laser itself, the motion platform, and the beam delivery system. It contains cutting parameters for numerous materials and can store part libraries to enable simple push button operation. It can even perform part nesting to optimize material utilization.

Small Footprint

Even though LaserCube offers a 4' x 4' cutting bed size, exceptional build quality, and a wide range of capabilities, it still only occupies 5.7 m² of floor space. And this includes the fiber laser, which can be mounted within the workstation cabinet to minimize floor space.

LaserCube – From a Company as Reliable as the Product

If your production depends on a machine tool, then you already understand that the system supplier is just as important as the hardware. For laser machines in particular, getting the most – in terms of productivity, uptime, and cost-effectiveness – requires a vendor who can deliver training, support, service, parts, and accessories quickly. And who can do so wherever in the world they’re needed. As a global company and leader in fiber laser technology, IPG offers the resources and support fabricators need to stay up and running

Getting Started with Laser Cutting

If you are considering the LaserCube system for small part manufacturing, IPG can help. Getting started is easy – send us a sample, visit one of our global application labs, or just tell us about your application.