Long-standing wisdom about cutting thick metal with fiber lasers has gradually become outdated. And an updated analysis of the relative capabilities of laser cutting and plasma cutting has become necessary.

High-power fiber lasers – which are now available in powers exceeding 100 kilowatts — have flipped the script, challenging many long-held assumptions about cost, speed, and performance. Most critically, these higher power fiber laser cutters are no longer primarily limited to thin metals: they now consistently outperform plasma cutters at material thicknesses exceeding 2 inches (50 mm).

This modernized guide provides a summary of the technological breakthroughs driving these changes and a data-driven comparison between fiber lasers and plasma cutters before answering the critical question: when is a laser cutter actually more economical than a plasma cutter?

This information should help you decide if a laser cutter can deliver the performance, productivity, and ROI that satisfies your production requirements.

Technological Advancements in High-Power Fiber Lasers

The most significant advances have been in the pump diode technology that powers fiber laser sources. The output power achievable by a single emitter has risen several orders of magnitude, from a fraction of a watt to several dozen watts.

Simultaneously, diode electrical efficiency has grown from around 20% to roughly 70%.

These core advancements have driven down the cost-per-watt down by a factor of 100 while also increasing reliability and operational lifetime.

System-Level Improvements for Thick Metal Cutting

Raw laser power alone isn’t enough to cut thick metal efficiently. Progress in other cutting system components has also been essential.

- Improved beam delivery: Multi-mode fiber lasers, paired with cutting heads built specifically for high-power operation, now maintain tight beam focus over greater cutting depths. This is supplemented by optical techniques like beam wobble and dynamic focus modulation.

- Optimized assist gas delivery: Modern systems feature improved assist gas delivery that ejects molten material more efficiently during the cut. This is crucial for achieving clean cuts in thicker materials while maintaining high cutting speeds.

- Enhanced thermal management: High-power laser cutting generates significant heat. Advanced cooling, more efficient optics, and smarter system control allow fiber lasers to remain stable under continuous high thermal loads.

Performance Analysis: Fiber Laser vs. Plasma Cutter

It is already well-established that laser cutting offers significant advantages over plasma technology. Lasers deliver higher precision, produce a narrower and straighter kerf, and create a much smaller heat-affected zone (HAZ). Cleaner edges mean that laser-cut features are frequently weld-ready and do not require post-processing.

Lasers can also accurately produce small holes with excellent roundness and little taper. This can save time and sometimes eliminates the need for secondary holemaking operations or drilling equipment.

Fiber Laser Cutting: Faith in a Higher Power

However, conventional wisdom has suggested that lasers are slower than plasma for cutting mild steel above 1 inch (25 mm) thick (and half that for stainless steel).

This used to be (more or less) true. But it is no longer the case.

To see how that has changed with the emergence of widely available high-power fiber lasers, let’s review some actual (and more current) cutting data.

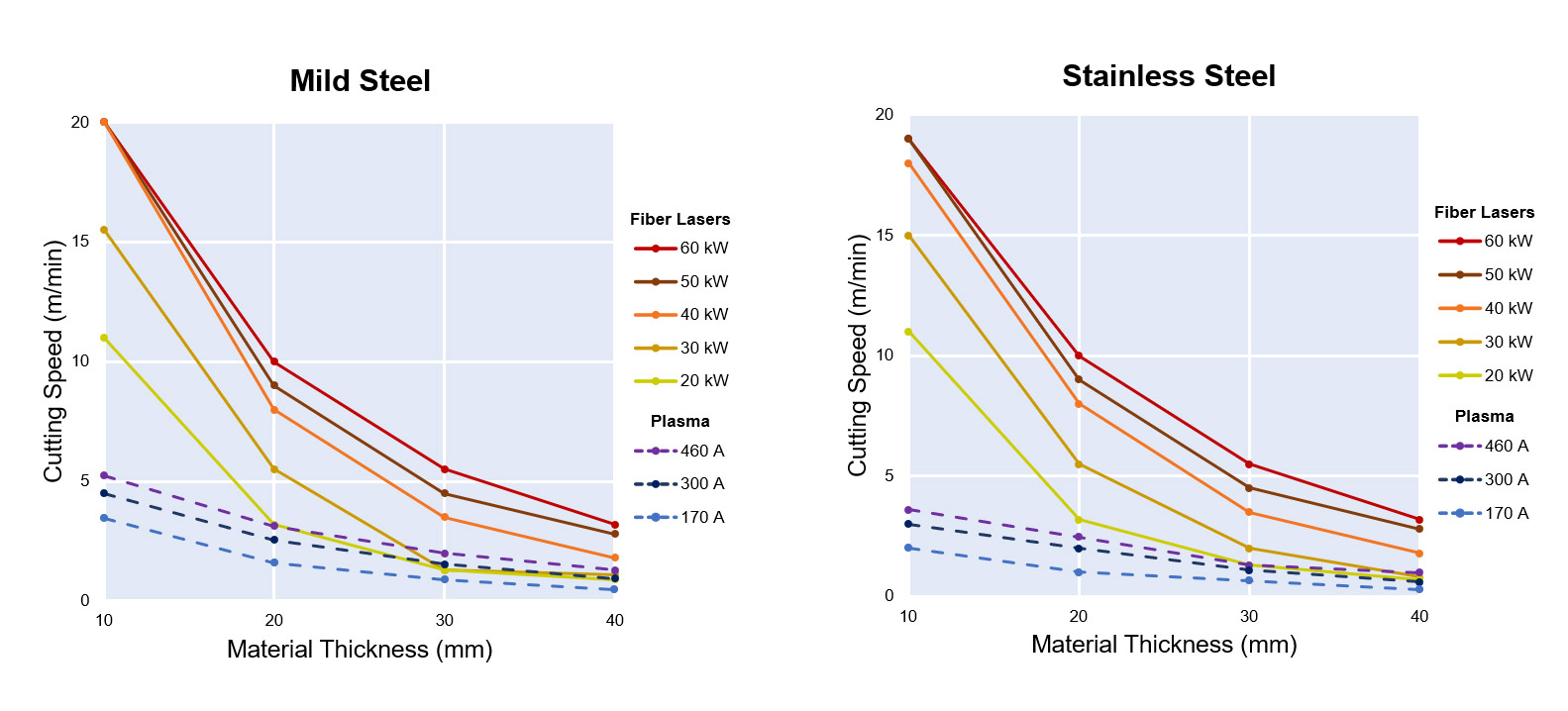

The graphs above chart cutting speed relative to material thickness, comparing best-in-class fiber laser and plasma cutting technology.

These plots for mild steel and stainless steel show that high-power fiber lasers almost always cut at higher rates than plasma cutters for materials from 10 mm to 40 mm thick. Even on 40 mm thick material, a 60 kW laser cuts mild steel about 2.5X faster than a 460 A plasma cutter. For stainless steel of the same thickness, the advantage increases to 3.2X faster.

The data shows that plasma cutters only perform better than fiber lasers when laser power is decreased to 30 kW or lower. And only when cutting thicker sections.

Understanding Assist Gas

The fastest and cleanest way to cut steel with a fiber laser is using a mixed assist gas (nitrogen with a small amount of oxygen). Every cutting test represented on the charts above where laser outperformed plasma used mixed assist gas.

However, once a sufficiently low laser power-to-thickness ratio is reached, it becomes necessary to switch to pure oxygen. Oxygen assist gas prevents the laser cutting process from stalling but at a necessarily lower rate and while producing a lower quality edge. Pure oxygen was required in the tests where laser cutting performed worse than plasma cutting.

Fortunately, this problem is completely eliminated when using a more powerful laser. When using a laser in the 40 kW or higher power range, mixed assist gas is ideal for cutting all but the thickest metals (well in excess of 40 mm).

Ultimately, this means that fiber lasers of 40 kW and above cut steel faster than plasma – often by a very significant factor – for the vast majority of cutting applications. And they accomplish this while also delivering cleaner, straighter edges with minimal dross.

ROI Analysis: When Does a Fiber Laser Make Sense?

High-power fiber lasers outperform plasma cutters in speed, quality, and consistency, but they also cost more to purchase. Fortunately, their higher throughput can quickly earn back that extra capital expense.

Most operating costs – amortization, labor, overhead, and maintenance – are tied to owning and operating the system, not how fast it cuts. Electricity and other consumables do increase with system power and use, but don’t scale in proportion to the extra throughput. So, if laser and plasma cutters cost roughly the same to operate over a month (which they do), the machine that produces more output over that time will always be the more economical one.

A Cost and Output Example

Let’s compare a 40 kW fiber laser to a 300 A plasma cutter using the data from earlier.

The 40 kW fiber laser cuts 20 mm thick mild steel at approximately 8 m/min. At full utilization, it can make about 38,000 meters of cuts per month.

The 300 A plasma cutter works at roughly half that speed, yielding about 19,000 meters in the same period.

We can accurately estimate that both systems cost about $20,000 per month to operate at these utilization levels.

If the product requirement is approximately 38,000 meters, one laser cutter meets the demand. Achieving the same output with plasma cutting requires two machines, doubling the monthly operating cost to $40,000.

If the single laser costs $400,000 more to purchase than the two plasma cutters, that $20,000 in monthly savings makes up the price difference in just 20 months.

Is a High-Power Fiber Laser Cutting Machine Right for You?

Laser cutting delivers the best value and fastest ROI under specific conditions. Considering investing in a high-power fiber laser if your operation involves:

- High utilization: The machine is kept busy enough for throughput-driven savings to accumulate quickly.

- Clean edge requirements: Reduced (or eliminated) post-processing turns directly into labor and equipment savings.

- Welded assemblies: Weld-ready laser edges cut prep time and improve downstream flow.

- Fine features: Lasers can create small holes and tight contours in a single operation.

- Floor space is limited: One high-power laser can replace multiple plasma cutters and shrink the required footprint.

- Part geometry is complex: Intricate shapes, tight radii, and internal features favor laser cutting over plasma every time.

Getting Started with a Laser Cutting Solution

As fiber laser technology continues to advance and the capabilities of laser machines increase, deciding between a laser cutter and a plasma cutter becomes more complicated.

For many fabricators and manufacturers, lasers have become an ideal tool for metal cutting. For others, plasma cutting remains more practical.

Talk to one of our laser cutting experts to see what kind of results and ROI you can expect in your application.