Tooling is often treated as an afterthought in automation projects. But when lasers are involved, it becomes a critical design element. Whether it’s welding, cutting, or surface treatment, lasers systems demand a higher level of tooling precision, consistency, and repeatability than other process technologies. Even the best laser equipment can’t overcome poor part presentation.

The role of tooling is deceptively simple: secure and orient the workpiece so the laser can do its job. But doing that reliably, across thousands of cycles – while accounting for variations in part geometry, operator loading, thermal distortion, and beam access – is often anything but simple.

Here we’ll outline the key considerations when designing tooling for laser automation. And most importantly, we’ll highlight why laser tooling requires a different mindset. This will help you to create better tooling and also understand why most automation equipment suppliers often aren’t equipped to satisfy your tooling requirements.

Laser Tooling Requirements

Laser processes are generally less forgiving of poor fixturing than other methods, especially laser welding. While methods like MIG welding might tolerate small gaps or misalignment, lasers require tighter tolerances and higher repeatability.

For example, fillet welding with inconsistent part edge location can produce weld gaps, undercutting, and reduced weld strength. Therefore, tooling must ensure good fit-up for welding applications (typically much less than 0.040"), as well as consistent standoff distances and beam access across complex geometries.

Laser systems also demand consistency – and overall automation yields benefit greatly from repeatable inputs. If parts shift, deflect, or vary from one cycle to the next, the laser can’t always compensate. Effective tooling ensures the process happens in the same place, every time.

Then there’s the issue of thermal input. While laser processes are fast, long welds or repeated exposure can still introduce heat-induced distortion. Tooling must anticipate and counter these forces before they negatively impact the finished weldment.

The part itself is also integral to the tooling design (and often the entire automation process). A common mistake is to utilize a laser process for its production, quality, and precision without considering optimizing the part design to take full advantage.

Sometimes a relatively minor change, such as switching from a fillet to a lap joint, can make a laser process more reliable and better support laser-friendly tooling. But these types of optimizations aren’t always obvious to tooling suppliers who focus purely on part holding.

The Broader Role of Tooling

Beyond all the details just mentioned, it’s important to understand the overall part that tooling plays in your automation system and process. It doesn’t just secure the part. It affects how reliably, efficiently, and accurately the entire laser process performs.

This means that good tooling must be designed with the process in mind, not just the part. To do that effectively, it must fulfill four interdependent functions:

- Allow for efficient loading and unloading

- Hold parts securely and repeatably during the process

- Provide unobstructed access to processing locations for the laser beam

- Maintain mechanical integrity and reliability over time

Optimizing each of these requires different design strategies. And each presents potential pitfalls. Let’s explore them individually.

Loading/Unloading

Loading and unloading cycles directly impact automation productivity, safety, and uptime. Whether the system is fully automated or operator-assisted, the tooling must facilitate rapid, precise, and repeatable part placement.

For manually loaded parts, poorly designed fixtures can lead to alignment errors, operator fatigue, or even safety risks. Ideally, fixtures are designed in the context of their entire workcell. This means considering part orientation and clamping to optimize the interaction with both the operator and the automation system (path planning).

For high-throughput systems, minimizing load time is crucial. Features like self-locating nests or guide pins can be used to make part placement quick, easy, and error-proof.

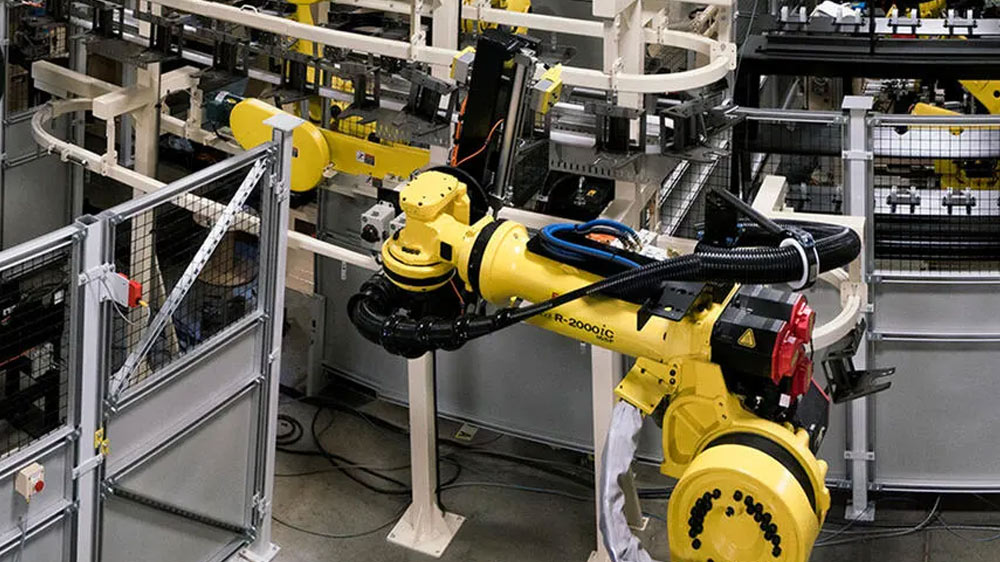

If part loading is robotic, the characteristics and capabilities of the robotic end-of-arm tooling (EOAT) must be factored in. This is necessary to ensure that the fixture interfaces reliably and repeatably with the EOAT, cycle after cycle.

Virtual tools can also be used to simulate loading sequences and validate reach and clearance zones during the design phase. This helps avoid surprises down the line and makes it more likely that automation systems will run smoothly under real world use conditions.

Part Holding

When it comes to part holding for laser automation, there is no one size fits all approach. Ultimately, every single application is unique.

At the same time, getting part holding right is nonnegotiable. Simply stated, no process – laser or otherwise – will work if it’s not performed in the right place.

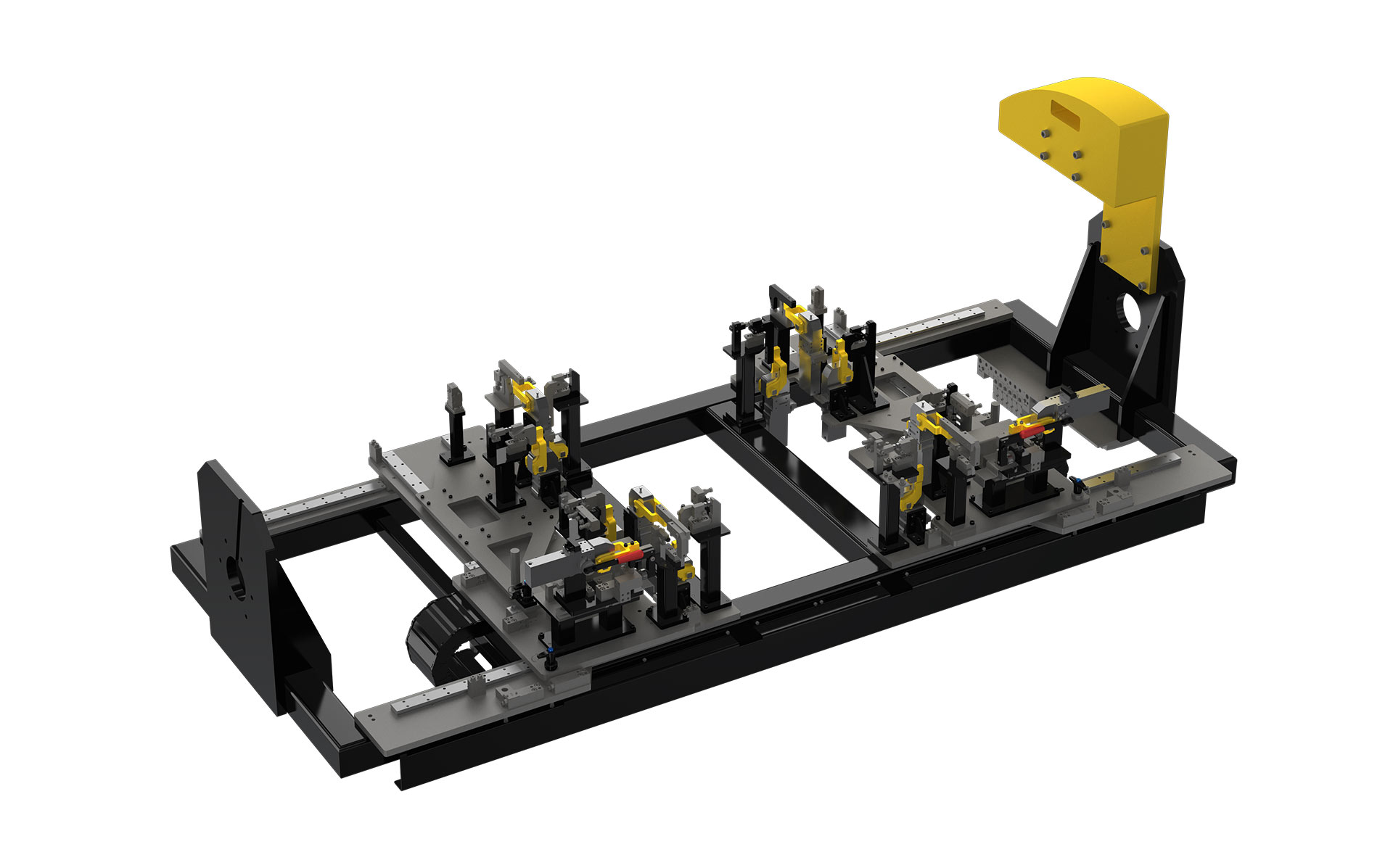

A laser welding fixture designed for quick part holding adjustments to account for multiple different part models.

But holding a part isn’t just about clamping. It’s about controlling variation. Even small shifts in datum alignment or slip-plane movement can throw off a laser process.

Fortunately, it is not always necessary to wait for prototyping and early production stages to identify problems caused by variation.

Often, tools like Variation Simulation Analysis (VSA) help reveal part holding issues before manufacturing ever begins. Part geometry, plus all the datums and tolerances, are input into VSA software. Various statistical methods are then used to predict how parts will shift in the tooling due to manufacturing variations, and how those shifts will affect things like weld location and cut accuracy.

Using VSA, it is possible to model how part tolerances and fixture design interact and predict whether the tooling will consistently position parts within process requirements. The analysis helps evaluate datum strategies and locate sources of variation that could affect quality. When issues are identified, VSA provides the insight needed to make changes to the fixture concept, part geometry, or weld joint design needed to improve process capability.

For welding in particular, Weld Distortion Analysis (WDA) models the thermal response of the part to identify where distortion might occur. Like with any form of VSA, if the modeled behavior reveals potential problems, changes can be made to the part, tooling, or process to eliminate them.

Process Access

No matter how effective the part holding, the process still won’t work if the laser beam can’t reach the process area or access it at the right angle. Process access is one of the most overlooked elements of tooling design.

It’s quite common for laser processes to require specific incident angles, clearances, or motion paths. Complex welds or process paths may require dynamic beam movement or even repositioning of the part mid-cycle. In cleaning applications, standoff distance is just as critical as lateral access.

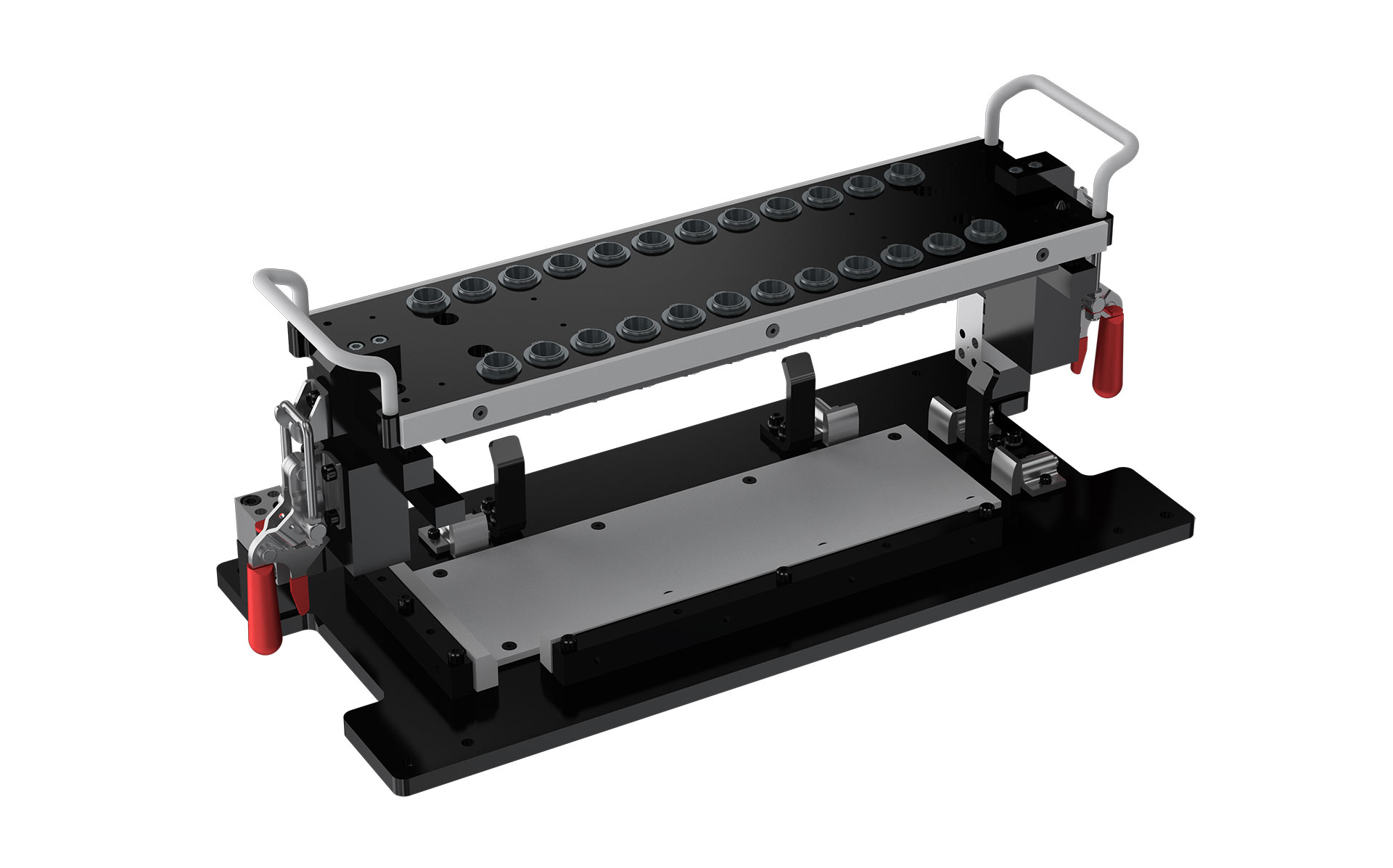

Tooling designed to clamp multiple features on a single part while allowing beam access for a high-speed laser scanning process.

Process access considerations can’t wait until integration. These choices must be made at the tooling design phase. Sometimes, tooling choices can even affect the specifications for the automation system itself (required robotic arm reach, for example).

Durability

Consistency is critical in any automated process. One key advantage of lasers over mechanical methods is that the laser tool itself never wears out. The higher process stability and near total elimination of tool replacement downtime are major reasons why lasers have become so popular in industrial materials processing.

Ideally, fixtures must also demonstrate a similar level of consistency over time. In laser systems, this means resisting wear from repeated clamping, thermal cycling, and possibly even occasional stray beam exposure.

Keep in mind that durability isn’t just about mechanical strength. The most important metric is repeatability over thousands of cycles.

Getting Started with Laser Automation

Successful laser automation depends on much more than just good equipment (although that’s important too). It hinges on the quality of the tooling that supports the process. Lasers demand tighter tolerances, more consistent part placement, and smarter fixture design than most other manufacturing methods. And while the laser itself doesn’t wear out in the same way as mechanical tools, long-term process stability still relies on tooling that maintains precision cycle after cycle.

With so many factors to consider, it is often worth working with an experienced laser integrator.

At IPG we work with you as a full laser automation partner, from laser-material analysis to process development, integration, ongoing support, and tooling design.

Getting started is easy – send us some sample parts, visit one of our global application labs, or just tell us about your application.