Surface cleaning is performed in fields ranging from aerospace and nuclear decontamination to bakeries and art conservation. And, while the particular materials and processes involved are as diverse as the industries that employ them, nearly all these various applications share a certain core requirement. Namely, the need to completely remove a surface layer without damaging or altering the material underneath.

Lasers offer unique advantages for these material removal and surface preparation tasks. They can thoroughly remove selective layers of material while producing virtually no effect on the surface underneath. Plus, laser cleaning is typically faster and more environmentally friendly than other methods. For these reasons, laser cleaning is experiencing increasing adoption in many applications and industries.

Here we’ll go over the basics of laser cleaning (also known as laser ablation and laser blasting) and discuss how to select the right system for your specific application.

Traditional Surface Cleaning

Typical surface cleaning processes include:

- Degreasing or removing oil and other residues before welding, coating, or bonding

- Cleaning rust and other oxides from metals

- Paint stripping

- Decoating – partially (rather than totally) removing a layer such as varnish or primer

- Removing release agents from tire, plastics, food, and composite molds

- Wire insulation stripping

- Cleaning and restoration of stone monuments and architectural facades

- Nuclear decontamination – removal of radioactive surface layers from pipes, tanks, containment structures, and other reactor components

Several non-laser methods have long been used for these various surface cleaning tasks. Most of these can be broadly grouped into three categories – abrasive blasting, chemical solvents, or mechanical techniques. It’s worth reviewing each.

Abrasive Blasting

How It Works:

Propels sand, glass beads, dry ice, or other solid particles at high velocity to mechanically remove coatings or contaminants.

Primary Advantages:

- Fast and inexpensive

- Simple to implement

- Can texture a surface when roughness is desired

Major Drawbacks:

- Imprecise, may damage or roughen substrates

- Generates dust and waste that must be collected or replaced

- Requires consumable media and nozzle maintenance

- Noisy, often needs sound-insulated enclosures

Chemical Cleaning

How It Works:

Uses acids, alkalis, solvents, or reactive solutions to dissolve, loosen, or lift contaminants while leaving the base material largely unaffected.

Primary Advantages:

- Can process large areas or complex internal geometries like bores or channels

- Produces chemically clean, bond-ready surfaces

Major Drawbacks:

- Involves hazardous chemicals requiring strict handling and costly disposal

- Poses health and environmental risks

- High throughput requires bulky, dedicated equipment

Mechanical Grinding/Brushing

How It Works:

Uses abrasive wheels, brushes, or tools in direct contact with the surface to scrape, cut, or wear away unwanted material.

Primary Advantages:

- Simple, well-understood process

- Removes heavy scale or coatings quickly

Major Drawbacks:

- Can gouge or distort surfaces

- Inconsistent results

- Unsuitable for complex shapes or precision parts

- Generates dust and debris that must be collected

The Need for Better Technology

Each of these legacy methods can be effective and they all continue to have their uses. But several factors are increasingly motivating manufacturers to seek a better approach.

One of the key drivers for change is a cross-industry need to support ever higher levels of process precision and repeatability. Plus, novel materials – used in products ranging from advanced composites to battery components – demand gentler, more selective cleaning than what is possible with traditional techniques.

Another agent of change is consistent economic pressure on manufacturers to lower operating and consumables costs, as well as to reduce the downtime associated with maintenance and cleanup. Furthermore, companies of all sizes are continuing to focus on processes well-suited to automation and that are compatible with modern process control techniques.

Finally, manufacturers all over the globe are facing ever stricter environmental and safety regulations. Compliance with these rules necessitates the elimination of hazardous chemicals, reductions in water usage, and decreases in waste production.

Laser Cleaning Basics

Laser cleaning was developed specifically to overcome the limitations of older cleaning methods. It offers a process that is more fully compatible with modern production environments and higher precision manufacturing. And it’s greener, more sustainable, and more cost-effective.

Let’s review the basics of laser cleaning to understand how it accomplishes these goals.

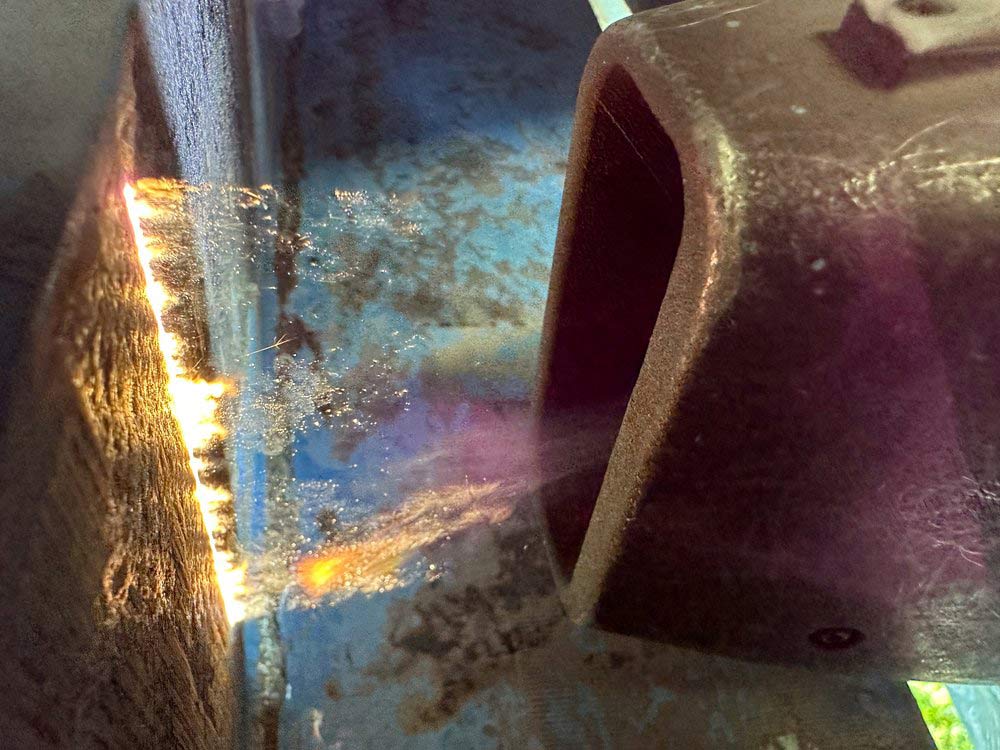

In laser cleaning, short duration, high-energy pulses of laser light are focused and scanned across a surface to strip away an unwanted coating or contaminant. Laser parameters are carefully chosen so that the surface layer strongly absorbs the light, while the underlying material either reflects it or minimally absorbs it.

This preferential absorption of laser light in the overlying material enables efficient removal. However, the exact mechanism of this removal depends on the specific laser parameters and properties of the substrate. It can involve direct ablation, heating and rapid vaporization, shockwave-driven spallation, or even photochemical decomposition of the surface layer.

No matter the particulars, laser cleaning offers excellent precision and control because the material removal rate and depth can be accurately tuned by adjusting laser parameters such as pulse energy, pulse duration, repetition rate, and scanning speed, Thus, laser cleaning can be optimized to work both with delicate surfaces and achieve aggressive removal rates.

Laser cleaning is also spatially selective, meaning it can remove contaminants from a specific area on a surface without affecting adjacent material. Laser cleaning offers such precise targeting that it can be used to remove material in surface areas less than a square millimeter in size.

Additionally, laser cleaning is contact-free. It introduces no mechanical stress, leaves no grit or residue, and doesn’t produce wear, surface damage, or heat-based distortion. Contact free operation also minimizes consumable use while avoiding solvents (and all the hazards and disposal issues related to them).

Finally, laser cleaning can be readily automated, either partially or fully. In many cases, it can be integrated inline with existing production flows. And because it can be automated and precisely controlled, laser cleaning delivers consistent results. All this produces a huge positive impact on cost, quality, yields, and throughput.

But that’s not to say that laser cleaning is right for every application. It is best suited for removing homogeneous and locally limited layers. Typically, it’s less economical for removal of layers over 0.5 mm in thickness, especially over large areas (several square meters). Laser cleaning is also less applicable to complex 3D parts, particularly those that block the line of sight of laser optics. And, finally, laser cleaning usually represents a higher capital cost than other methods – although its lower operating and consumables costs can quickly offset that.

Choosing a Laser Cleaning Solution

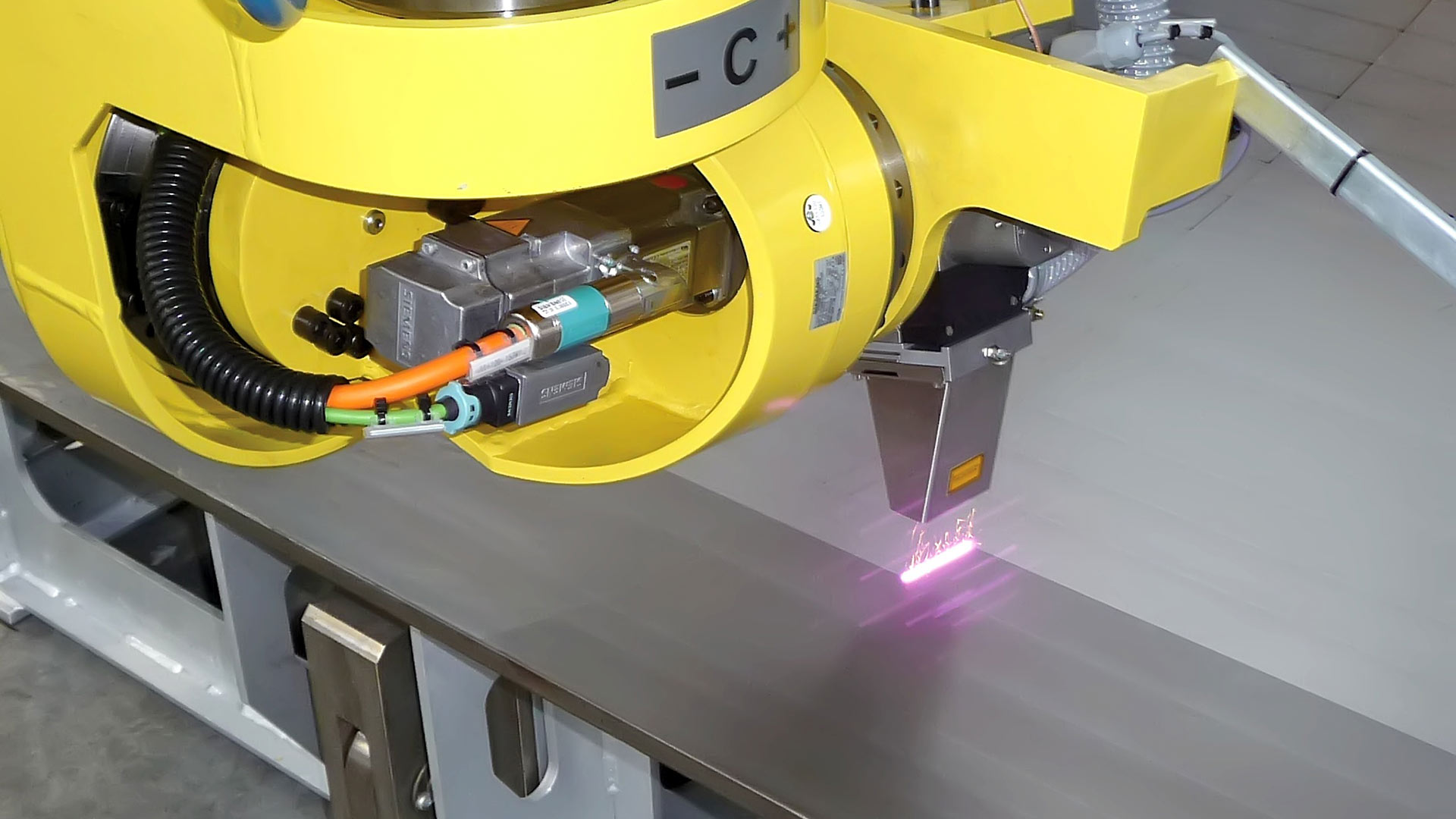

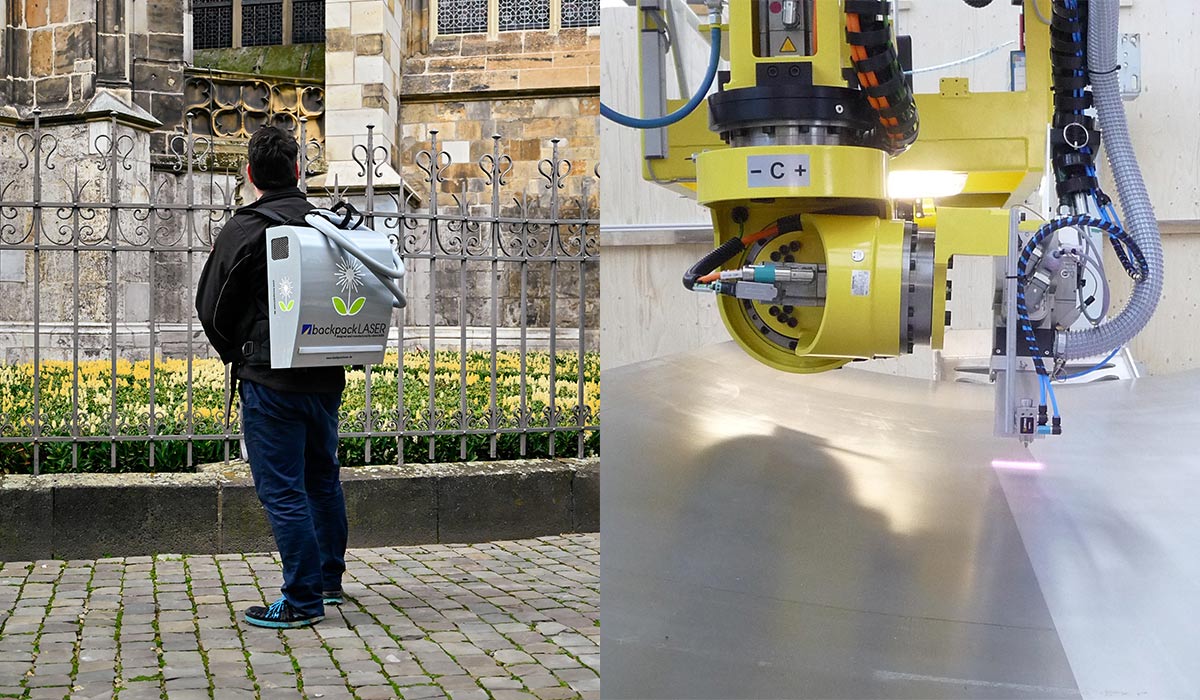

Laser cleaning products range from laser sources to handheld and portable devices to small semi-automatic enclosures to fully automated solutions designed for rapid processing of large components and assemblies.

Laser cleaning equipment ranges from extremely portable machines to large, automated systems.

The sheer number of options can seem overwhelming. So how do you cut through that complexity to identify the right product for your application?

The best approach is usually to first consider the contaminant type, then the substrate material, and then practical considerations such as throughput and integration. Let’s examine the typical requirements for each of these factors.

Step #1: Identify the contaminant

| Contaminant Type | Typical Removal Need | Laser Requirements |

| Light organics (oils, grease) | Gentle surface cleaning | Low fluence, high repetition rate |

| Paints, varnishes | Controlled layer removal | Moderate fluence, adjustable parameters |

| Rust, oxides, scale | Deep, aggressive removal | Higher fluence, high peak power |

| Multi-layer coatings | Selective, precise removal | Tunable pulse width & energy |

| Residues on sensitive substrates | Very gentle removal | Shorter wavelength (green/UV), low fluence |

Step #2: Categorize the substrate material

| Substrate | Best Wavelength | Description |

| Metals | Infrared (IR) | Strong absorption contrast for oxides and coatings |

| Polymers/Composites | IR, Green, or UV | Reduces heat and surface alteration |

| Ceramics/Glass | IR, Green, or UV | High precision and minimal thermal damage |

| Mixed or layered materials | Multiple | May require multi-pass or multi-wavelength approach |

Step #3: Define the process requirements

| Requirement | Best Solution |

| Small area/low volume processing | Handheld or portable unit |

| Medium throughput | Standalone workstation |

| Continuous production | Inline automated, robotic, or conveyor-integrated system |

| Non-flat surface processing | Handheld, robotic, or specialized optics, depending on the application |

| On-site or field use | Backpack or mobile system |

Step #4: Consider integration & operational factors

| Factor | Common Considerations | Significance |

| Automation | PLC/fieldbus/compatibility, digital I/O, integration support, process monitoring | Enables seamless inline operation and coordinated control with other production equipment |

| Safety | Enclosures, interlocks, beam shielding, dust/fume extraction | Ensures operator safety, meets regulatory requirements, and prevents contamination |

| Environment | Compact footprint, proper ventilation, ambient condition tolerance | Guarantees stable performance and easy installation within existing facility constraints |

| Cost | Low consumable usage, long laser lifetime, minimal maintenance requirements | Reduces total cost of ownership and improves ROI |

| Scalability | Modular power options, upgradeable optics, flexible software | Future-proofs the system and adapts to evolving production needs |

Getting Started with Laser Cleaning

Considering integrating a handheld or automated laser cleaning tool into your operation?

Getting started is easy – send us a sample, visit one of our global application labs, or just tell us about your application.