- Home

- Solutions

- Laser Application Development

- Virtual Engineering

Virtual Engineering & Simulation

Bridging the Gap Between Prototype & Production

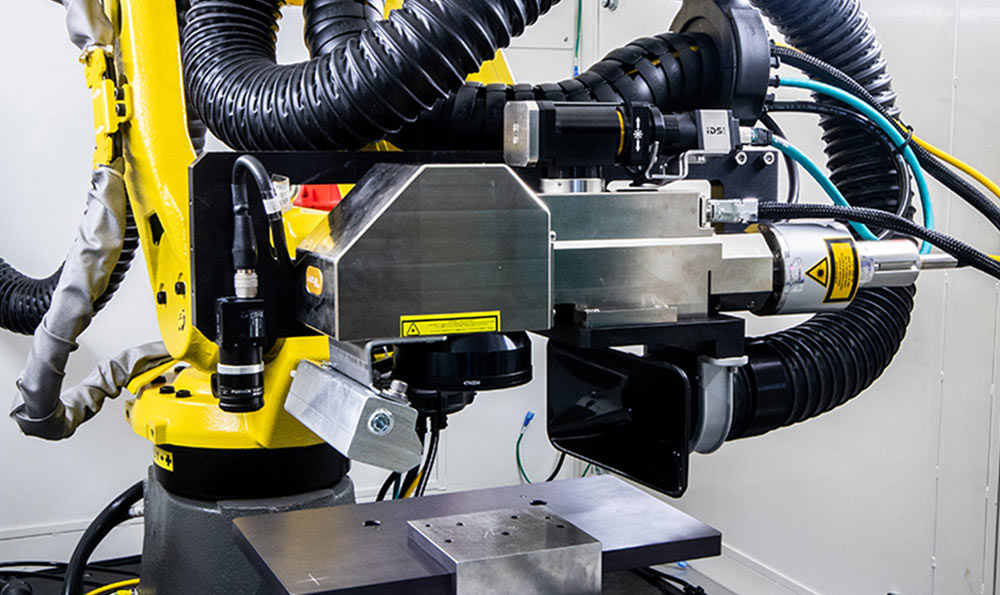

Finding success in a laser application sometimes requires more than just optimizing laser-material interaction. It can also mean designing parts, products, and workflows to take full advantage of the power of laser processing.

That's where we come in. From helping you design for manufacturability to simulating weeks of real-time production in seconds, our team of laser automation experts helps reduce risk, lower costs, and deploy solutions faster.

Talk to a Laser Automation ExpertCapabilities & Techniques

3D Simulation

3D simulation provides a virtual representation of your automated laser solution, allowing you to visually evaluate different scenarios, identify potential issues, and optimize workflows prior to deployment.

Finite Element Analysis

We use finite element modeling to simulate how a part or assembly will perform in real life applications. This allows our engineers to discover potential design flaws before prototyping begins.

Robotic Simulation

Analysis of the laser solution's robotic elements allows us to identify the best robotic arm for the process and evaluate its motion, collision risks, and workspace coverage to ensure optimal robotic integration.

Variation Simulation Analysis

We use Variation Simulation Analysis (VSA) to evaluate how manufacturing and assembly variations might impact the final product. This 3D tolerance analysis helps optimize datums and tolerances, reduce costs, and improve process reliability.

Weld Distortion Analysis

By analyzing heat input, fixturing, sequencing, material properties, and joint designs, Weld Distortion Analysis (WDA) identifies potential deformation issues before manufacturing begins to optimize fixturing and welding parameters.

Offline Programming

For robotic solutions, our engineers test programs in a virtual environment to simulate robotic tasks before implementation. Offline programming optimizes robotic processes and enables faster deployment.