Option 1:

IPG Controls & Software

Pulse Duration

Wavelengths

Working Field

Pulse Duration

Wavelengths

Working Field

IPG integrated markers and scanners are available with powerful and easy to use IPGScan software designed to take full advantage of the capabilities of IPG pulsed laser sources. Maximizing quality and productivity is easy with software packages that optimize marking, surface treatment, and cleaning applications.

IPG controllers and software platforms also provide an optional interface to external motion controller for both point-and-shoot and marking-on-the-fly applications as well as interfaces with PLCs and other process controllers.

For customers who want to use their own controller and software an industry standard XY2-100 interface is also available.

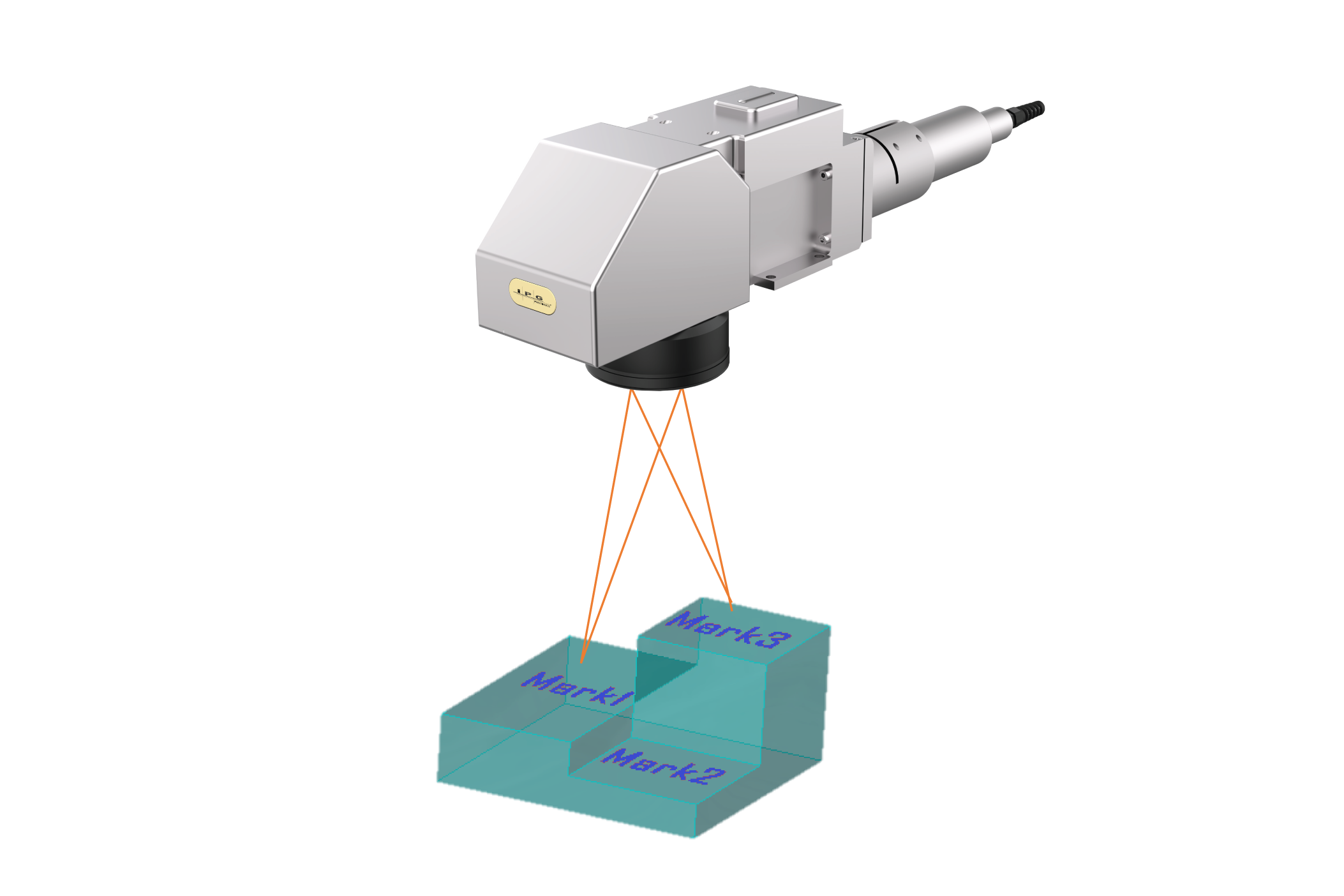

IPG integrated scanners and markers offer optional 3D scanning capabilities, allowing beam position and focus to be adjusted along the X, Y, and Z axes.

A wide Z-range and accurate focus position control further reduces the required system motion, making installation easier and more flexible.

IPGScan software makes executing marking and scanning tasks fast and easy. Import 3D models of parts, project marks and visualize laser paths, optimize your process sequence, and more.

Drag to see all 5 products![]()

|  |  |  |  |

| Infrared Integrated Laser Marker | Green Integrated Laser Marker | UV Integrated Laser Marker | IR Picosecond Integrated Laser Marker | IR Integrated 3D Laser Marker |

| Scanner & Nanosecond Laser | Scanner & Nanosecond Laser | Scanner & Nanosecond Laser | Scanner & Picosecond Laser | 3D Scanner & Nanosecond Laser |

| Laser Source | ||||

|---|---|---|---|---|

| Wavelength | ||||

| 1064 nm | 515 nm | 355 nm | 1030 nm | 1064 nm |

| Average Power | ||||

| 20, 30, 50, 100 W | 50 W | 3, 5, 6 W | 50 W | 20, 30, 50, 100 W |

| Pulse Energy | ||||

| up to 1 mJ | 50 to 500 μJ | up to 20 μJ | up to 25 μJ, optional 250 μJ burst | up to 1 mJ |

| Pulse Duration | ||||

| 80 to 120 ns | 1.5 to 10 ns | 1.5 ns | 2 ps | 80 to 120 ns |

| Pulse Repetition Rate | ||||

| 2 to 500 kHz | 10 to 1000 kHz | 10 to 1000 kHz | 50 to 2750 kHz, optional 5.5 MHz | 2 to 500 kHz |

| Scan Head | ||||

| Focus Lens / Scan Field (XY) | ||||

| 100 mm / 60 x 60 mm 163 mm / 110 x 110 mm 254 mm / 170 x 170 mm 330 mm / 204 x 204 mm 420 mm / 300 x 300 mm | 165 mm / 115 x 115 mm | 100 mm / 60 x 60 mm 163 mm / 110 x 110 mm 250 mm / 155 x 155 mm | 100 mm / 60 x 60 mm 163 mm / 110 x 110 mm 254 mm / 170 x 170 mm 330 mm / 204 x 204 mm 420 mm / 300 x 300 mm | 100 mm / 60 x 60 mm 163 mm / 100 x 100 mm |

| Focus Lens / Scan Field (Z) | ||||

| - | - | - | - | 100 mm / 18 mm 163 mm / 50 mm |

| Clear Aperture | ||||

| 12 mm | 12 mm | 9, 12 mm | 12 mm | 12 mm |

| Focusing Lens | ||||

| 100, 163, 254, 330, 420 mm | 165 mm | 110, 170, 250 mm | 100, 163, 254, 330, 420 mm | 100, 163 mm |

| Mounting Configuration | ||||

| Vertical or Horizontal | Vertical or Horizontal | Vertical or Horizontal | Horizontal | Horizontal |

| Learn More | Learn More | Learn More | Learn More | Learn More |

|

||||||||||||||||||||

| Laser Source | ||||||||||||||||||||

| Wavelength | 1064 nm | 515 nm | 355 nm | 1030 nm | 1064 nm | |||||||||||||||

| Average Power | 20, 30, 50, 100 W | 50 W | 3, 5, 6 W | 50 W | 20, 30, 50, 100 W | |||||||||||||||

| Pulse Energy | up to 1 mJ | 50 to 500 μJ | up to 20 μJ | up to 25 μJ, optional 250 μJ burst | up to 1 mJ | |||||||||||||||

| Pulse Duration | 80 to 120 ns | 1.5 to 10 ns | 1.5 ns | 2 ps | 80 to 120 ns | |||||||||||||||

| Pulse Repetition Rate | 2 to 500 kHz | 10 to 1000 kHz | 10 to 1000 kHz | 50 to 2750 kHz, optional 5.5 MHz | 2 to 500 kHz | |||||||||||||||

| Scan Head | ||||||||||||||||||||

| Focus Lens / Scan Field (XY) | 100 mm / 60 x 60 mm 163 mm / 110 x 110 mm 254 mm / 170 x 170 mm 330 mm / 204 x 204 mm 420 mm / 300 x 300 mm | 165 mm / 115 x 115 mm | 100 mm / 60 x 60 mm 163 mm / 110 x 110 mm 250 mm / 155 x 155 mm | 100 mm / 60 x 60 mm 163 mm / 110 x 110 mm 254 mm / 170 x 170 mm 330 mm / 204 x 204 mm 420 mm / 300 x 300 mm | 100 mm / 60 x 60 mm 163 mm / 100 x 100 mm | |||||||||||||||

| Focus Lens / Scan Field (Z) | - | - | - | - | 100 mm / 18 mm 163 mm / 50 mm | |||||||||||||||

| Clear Aperture | 12 mm | 12 mm | 9, 12 mm | 12 mm | 12 mm | |||||||||||||||

| Focusing Lens | 100, 163, 254, 330, 420 mm | 165 mm | 110, 170, 250 mm | 100, 163, 254, 330, 420 mm | 100, 163 mm | |||||||||||||||

| Mounting Configuration | Vertical or Horizontal | Vertical or Horizontal | Vertical or Horizontal | Horizontal | Horizontal | |||||||||||||||

| Learn More | Learn More | Learn More | Learn More | Learn More | ||||||||||||||||

The specifications above represent standard products. IPG can offer laser sources and scanners with customized specifications upon request.

Product availability may vary by region.