Safety Information and Conventions

To ensure the safe operation and

optimal performance of the LightWELD product, follow all warnings in the

product User Guide. Safety precautions must be observed during all phases of

operation, maintenance, and service.

To ensure the safe operation and

optimal performance of the LightWELD product, follow all warnings in the

product User Guide. Safety precautions must be observed during all phases of

operation, maintenance, and service.

Operators must adhere to these recommendations and apply sound laser safety practices at all times. Never open the module. There are no user serviceable parts, equipment or assemblies associated with this product. All internal service and maintenance should only be performed by qualified IPG personnel, except as noted in Section A of the User Guide.

Laser Classification

Governmental standards require that all lasers be classified according to their output power or energy and the laser wavelength.

This device is classified as a high power Class 4 laser instrument under 21 CFR, Subchapter J, part II, 1040.10(d).his product emits invisible laser radiation at or around a wavelength of 1070nm. The total light power radiated from the optical output is greater than 1500W average and >2500W peak per optical output port, depending on the model. Please refer to the product specification for the specific performance characteristics of your device.

This device is classified as a high power Class 4 laser instrument under 21 CFR, Subchapter J, part II, 1040.10(d).his product emits invisible laser radiation at or around a wavelength of 1070nm. The total light power radiated from the optical output is greater than 1500W average and >2500W peak per optical output port, depending on the model. Please refer to the product specification for the specific performance characteristics of your device.

This level of light may cause severe damage to the eye and skin. Due to these risks, a qualified laser safety officer should be present to ensure a safe working environment. Appropriate laser safety protection, guards and procedures shall be in place at all times while the laser is operational.

This level of light may cause severe damage to the eye and skin. Due to these risks, a qualified laser safety officer should be present to ensure a safe working environment. Appropriate laser safety protection, guards and procedures shall be in place at all times while the laser is operational.

This product also contains a guide laser that is Class 2M per IEC 60825-1 and Class 2 per 21CFR 1040.10(g). The guide laser emits visible laser radiation at or around a wavelength range of 600 to 700 nm and is capable of producing a peak power of 1mW. Eye or skin exposure should be avoided. Do not stare into the beam or view directly with optical instruments.

Please refer to the laser safety warning labels in section 2.2.5. of the User Guide

Warning

Class 4 - High Power Lasers present the most serious of all laser hazards. Take precautions to prevent accidental exposure to both direct and reflected beams. Diffuse and specular beam reflections can inflict severe retina and/or cornea injuries leading to permanent eye damage.

Class 4 - High Power Lasers present the most serious of all laser hazards. Take precautions to prevent accidental exposure to both direct and reflected beams. Diffuse and specular beam reflections can inflict severe retina and/or cornea injuries leading to permanent eye damage.

Laser welding systems may create specular reflections due to the interaction of the laser beam and the parts being processed. Highly reflective metals such as aluminum and copper may cause some portion of the beam energy to be reflected from the target weld site and require additional precautions. Specular reflections may also present a hazard to the operator if any portion of the beam is reflected from multiple surfaces. Take precautions to understand the expected cone of specular reflection for each processed part and do not attempt to view the part or place any part of the body within the expected specular reflection cone.

Class 4 laser beams are also a potential fire hazard and skin hazard as well.

When operating the device in the vicinity of others, all personnel must wear appropriate eye protection and take additional precautions to avoid harm from specular reflections. For information on laser safety eyewear, refer to section 2.2.4.

Use of controls, adjustments or performance of procedures other than those set forth in this User Guide may result in exposure to hazardous radiation.

Laser Safety Eyewear

Use appropriate laser safety eyewear when operating this device or in the vicinity of this device while in operation. The selection of appropriate laser safety eyewear requires the end user to accurately identify the range of wavelengths emitted from this product.

Use appropriate laser safety eyewear when operating this device or in the vicinity of this device while in operation. The selection of appropriate laser safety eyewear requires the end user to accurately identify the range of wavelengths emitted from this product.

Please review the safety labeling on the product and verify that the personal protective equipment (i.e. enclosures, viewing windows, or viewports, eyewear, etc.) being utilized is adequate for the output power and wavelength ranges. Decisions on safety eyewear must also take into account any secondary radiation hazards due to the welding process (see section 2.3.1).

Whether the laser is used in a new installation or to retrofit an existing system, the end user is solely responsible for determining the suitability of all personal protective equipment.

There are several laser safety equipment suppliers that offer materials or equipment. Some of them include LaserVision USA, Kentek Corporation and Rockwell Laser Industries. There are other laser personal protective equipment providers. IPG provides the names of these providers solely as a convenience and does not endorse or recommend any of them, or their products or services. IPG assumes no liability for their recommendations, products or services.

![]() Laser safety eyewear must conform to US and international safety standards, including 9 CFR 1926.102(b)(2), ANSI Z136.1 (US) and EN207/EN208 (Europe). The regulations in force will depend on the location of the laser installation.

Laser safety eyewear must conform to US and international safety standards, including 9 CFR 1926.102(b)(2), ANSI Z136.1 (US) and EN207/EN208 (Europe). The regulations in force will depend on the location of the laser installation.

Device Safety Label Locations

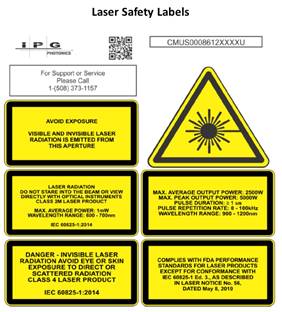

The safety label which is affixed on the device, provides information on the laser radiation hazards that are present in your particular device.

The safety label and the information listed on the safety label will vary based on the output power(s), wavelength(s), and other performance characteristics. It is important to review the labels affixed to the product for specific information about your laser device.

This product has the required safety labels located on the outside of the device enclosure at various locations. These include warning labels indicating removable or displaceable protective housings, apertures through which laser radiation is emitted and labels of certification and identification.

Important Welding Specific Safety Information

Secondary Radiation Hazard

Both visible and invisible light radiation will be produced during welding. The interaction between high power laser beams and target materials being welded may create plasmas that produce UV emissions and “blue light” which may cause conjunctivitis, photochemical damage to the retina and/or sunburn like reaction to the skin.

Both visible and invisible light radiation will be produced during welding. The interaction between high power laser beams and target materials being welded may create plasmas that produce UV emissions and “blue light” which may cause conjunctivitis, photochemical damage to the retina and/or sunburn like reaction to the skin.

Welders who are exposed, to invisible UV light without proper protection can suffer permanent eye damage. Even brief exposure to invisible UV light during welding can cause blurred vision, burning, tearing, eye pain and irritation (feeling of sand in your eye).

Protective Eyewear for Welding

Eye protection is required during laser welding to protect your eyes from any reflected or scattered Class 4 laser beams, but also to protect against welding bright light, UV light, heat and sparks.

Eye protection is required during laser welding to protect your eyes from any reflected or scattered Class 4 laser beams, but also to protect against welding bright light, UV light, heat and sparks.

For laser welding, it is not sufficient to wear PPE that only protects against the laser’s IR wavelength. The selection of PPE should also take into account the secondary radiation hazards discussed in section 2.3.1 as well.

EYE HAZARDS DURING WELDING - MANDATORY PPE!

A combination of face shields, helmets, glasses and/or goggles will offer the best protection during laser welding. For example, an additional welding helmet (with appropriate filter lenses) that protects the wearer from UV and visible radiation should also be worn over the laser safety eyewear. A welding helmet can also protect the welder from being injured due to hot splatter, metal particulates and sparks.

A combination of face shields, helmets, glasses and/or goggles will offer the best protection during laser welding. For example, an additional welding helmet (with appropriate filter lenses) that protects the wearer from UV and visible radiation should also be worn over the laser safety eyewear. A welding helmet can also protect the welder from being injured due to hot splatter, metal particulates and sparks.

All personnel working near the laser welding area must also wear laser safety eyewear, a welding helmet, and protective clothing.

Skin Hazard

Exposure to IR and UV light radiation during welding can injure the skin.

Exposure to IR and UV light radiation during welding can injure the skin.

Depending on the intensity of the IR light, skin injuries may include thermal burns or excessive dry skin. Exposure to UV light may cause skin burns that are similar sunburns and will increase a welder’s risk of skin cancer and accelerated signs of skin aging.

Welding sparks may also cause burns.

Laser material processing can transfer a significant amount of energy into a part. Parts may be extremely hot even after the welding process is complete. Ensure that the proper PPE is used to protect against potential burns.

Skin Hazards During Welding – Wear PPE

![]()

![]() Take precautions to prevent skin damage by wearing protective clothing such as fire-resistant gloves, caps, leather apron and other flame resistant clothing. Sleeves and collars should be buttoned.

Take precautions to prevent skin damage by wearing protective clothing such as fire-resistant gloves, caps, leather apron and other flame resistant clothing. Sleeves and collars should be buttoned.

Fire Hazard

![]() If combustible or flammable materials are nearby to the welding area, the heat and sparks produced during welding are capable of starting a fire or causing an explosion. Laser welding should only be performed if the area is free of combustible materials.

If combustible or flammable materials are nearby to the welding area, the heat and sparks produced during welding are capable of starting a fire or causing an explosion. Laser welding should only be performed if the area is free of combustible materials.

Never weld on containers that have flammable or combustible material. If the contents of a container are unknown, you should assume that they are flammable or combustible.

Fire extinguishers should be nearby, accessible and personnel trained in their usage.

Fume Hazards

Welding “smoke” can be comprised of very fine particles and gases. Welding fumes and gases come from a combination of the material being welded or any filler material used, shielding gases used, paints, coatings, chemical reactions, and air contaminants. Welding smoke can adversely affect the lungs, heart, kidneys and central nervous system.

Welding “smoke” can be comprised of very fine particles and gases. Welding fumes and gases come from a combination of the material being welded or any filler material used, shielding gases used, paints, coatings, chemical reactions, and air contaminants. Welding smoke can adversely affect the lungs, heart, kidneys and central nervous system.

When the laser interacts with target materials such as plastics, metals, composites, the target material may start to vaporize. Often the fumes and mists cannot be seen, but are very toxic and pose a serious health hazard.

Welding in a poorly ventilated confined space is extremely dangerous. Dangerous concentrations of toxic fumes and gases can build up very quickly causing unconsciousness or death from suffocation.

UV emissions given off during the welding process can react with the oxygen and nitrogen in the air to form ozone and nitrogen oxides which at high concentrations can be deadly.

Shielding gases used during welding can displace the air and cause injury or death.

During welding, keep your head away from the fumes. Always weld in an area with adequate ventilation to insure breathing air is safe.

Hazardous fumes and vapors need to be captured and exhausted (refer to section 2.6.3). Use a fume extraction system to remove vapors, particles, and hazardous debris from the welding processing area.

Read and obey the safety data sheets and warning labels for all welding materials used.

In confined spaces and other circumstances, the use of a respirator may also be required.

Routine air monitoring should be conducted to determine the levels of hazardous fumes in the welding area.

Gas Cylinder Safety

The gas cylinder may explode if damaged or placed nearby to the welding area.

![]() Shielding gas cylinders should be located in areas where they cannot be struck or damaged. Place them away from sources of heat, sparks or flame.

Shielding gas cylinders should be located in areas where they cannot be struck or damaged. Place them away from sources of heat, sparks or flame.

Cylinder must be stored upright and secured to a fixed support.

Need to have working regulators that are suitable for the gas and pressure required. All hoses and fittings should also be suitable for the application and maintained in good working condition.

Welding Related Safety Resources

OSHA standards for welding cutting and brazing:

https://www.osha.gov/SLTC/weldingcuttingbrazing/standards.html

NFPA 51B “Standard for Fire Prevention During Welding, Cutting and Other Hot Work”, available from: NFPA, 1 Batterymarch Park, Quincy MA 02169

CGA publication P-I “Precautions for Safe Handling of Compressed Gases in Cylinders”, available from: Compressed Gas Association, 1401 George Carter Way, Chantilly, VA 20151 For laser safety resources refer to section 2.7.

General Safety Instructions

IMPORTANT

![]() If this device is used in a manner not specified in this document, the protection provided by the instrument may be impaired and the warranty will be voided.

If this device is used in a manner not specified in this document, the protection provided by the instrument may be impaired and the warranty will be voided.

Specular Reflections

Often there can be numerous secondary laser beams produced at various angles near the laser output aperture. These beams are called “Specular Reflections” and are produced when the laser light reflects off a surface where the primary beam is incident.

Although these secondary beams can be less powerful than the total power emitted from the laser, the intensity can be great enough to cause damage to the eyes and skin as well as materials surrounding the laser.

![]() Exercise caution to avoid / minimize specular reflections, including but not limited to wearing laser safety goggles

and a welders mask. This product emits invisible laser radiation at or around a wavelength of 1070nm (infrared).

Exercise caution to avoid / minimize specular reflections, including but not limited to wearing laser safety goggles

and a welders mask. This product emits invisible laser radiation at or around a wavelength of 1070nm (infrared).

In addition, this product emits visible laser radiation at or around a wavelength of 600-700 nm (red).

Establish a Laser Controlled Area

![]() For more information on setting up a laser controlled area, your site Laser Safety Officer should refer to the most recent revision of:

For more information on setting up a laser controlled area, your site Laser Safety Officer should refer to the most recent revision of:

American National Standards Institute publication ANSI Z136.1 (US) or,

IEC 60825-4 Safety of Laser Products - Part 4: Laser Guards (Europe).

In many jurisdictions, laser safety regulations require the appointment of a site Laser Safety Officer (LSO). Work with your site LSO to establish a laser controlled area (LCA) to protect all personnel working in the area from being directly or indirectly exposed to the laser beam. The LSO is responsible for conformance and enforcement of laser safety regulations. In addition, the LSO ensures that laser protective eye-wear, clothing and shields are available and being used.

Ensure that all personal protective equipment (PPE) is suitable for the output power and wavelength range listed on the laser safety labels that are affixed to the product. Any PPE must also be suitable for any secondary radiation.

Use the laser in a room with access to the LCA controlled by door interlocks.

Provide suitable barriers to secure a laser safe work area and to prevent the beam from escaping the area. Any barriers used in the LCA should be made of a laser-safe material that can withstand direct and diffusely scattered beams.

Post warning signs outside the LCA when the laser is in use. Appropriate warning signs should be posted throughout the controlled area, especially at any entrances to and from the area. For example, a sign warning of potential eye hazard should be placed outside the entrance to the enclosed controlled area.

Restrict access in the LCA to only those individuals who are trained in laser safety while operating the laser. Post a sign with the names of all persons authorized to work within the laser work area.

WARNING

![]() NEVER look directly into a laser aperture (such as the output fiber, or weld head) while the unit is powered. User must (1) turn keyswitch to “OFF” position and (2) disconnect the AC power.

NEVER look directly into a laser aperture (such as the output fiber, or weld head) while the unit is powered. User must (1) turn keyswitch to “OFF” position and (2) disconnect the AC power.

Wear appropriate laser safety eyewear and a welders mask at all times while operating the product. Personnel in the vicinity must also wear the same safety gear. Ensure that all personal protective equipment (PPE) is suitable for the output power and wavelength range listed on the laser safety labels that are affixed to the product.

· NEVER look directly into the output port when power is supplied to the laser.

· Avoid positioning the laser and all optical components at eye level.

· Avoid using the laser in a darkened environment.

· Provide enclosures for the laser beam.

· Always turn the key to the OFF position when working with the output (i.e. mounting the laser head into a fixture, etc.). As an added precaution, remove the key from the keyswitch during such work.

CAUTION

![]() Do not install or terminate the laser head when laser is active. Always ensure the key is in the “OFF” position and unit is disconnected from AC power when performing these tasks.

Do not install or terminate the laser head when laser is active. Always ensure the key is in the “OFF” position and unit is disconnected from AC power when performing these tasks.

Equipment and Solvents

Light-sensitive elements in equipment, such as video cameras, photomultipliers, and photodiodes can also be damaged from exposure to the laser light.

WARNING

![]() Laser light is strong enough to burn skin, clothing, and paint. The laser can cut and weld metal. Laser light can ignite volatile substances such as alcohol, gasoline, ether and other solvents.

Laser light is strong enough to burn skin, clothing, and paint. The laser can cut and weld metal. Laser light can ignite volatile substances such as alcohol, gasoline, ether and other solvents.

Exposure to solvents or other flammable materials and gases must be avoided and considered when installing and using this device.

Electrical Safety

WARNING

![]() The input voltage to the laser is potentially lethal. All electrical cables and connections should be treated as if they were at a harmful level.

The input voltage to the laser is potentially lethal. All electrical cables and connections should be treated as if they were at a harmful level.

All parts of the electrical cable, connector or device housing should be considered dangerous.

WARNING

![]() All electrical and weld gas connections must be connected prior to applying power to the unit.

All electrical and weld gas connections must be connected prior to applying power to the unit.

In addition and where applicable, all connections must be secured with screws to ensure proper functionality. To ensure electrical safety:

Make sure the device is properly grounded through the protective conductor of the AC power cable. Any interruption of the protective grounding conductor from the protective earth terminal can result in personal injury.

Before supplying the power to the device, ensure that the correct voltage of the AC power source is used. Failure to use the correct voltage can cause damage to the device. Refer to the markings on your specific model for proper electrical supply connection.

There are no operator serviceable parts inside. Refer all servicing to qualified IPG personnel. To prevent electrical shock, do not remove covers. Any tampering with the products voids the warranty.

Connections to external circuits except for Mains connections: the external connections between this product and other external devices are PELV (Protected Extra-Low Voltage) as defined by IEC 61140. Non-Mains outputs of other devices connected to this product should also be PELV or SELV (Safety Extra-Low Voltage).

Environmental Safety

WARNING

![]() Ensure that all personal protective equipment (PPE) is suitable for the output power and wavelength range listed on the laser safety labels that are affixed to the laser.

Ensure that all personal protective equipment (PPE) is suitable for the output power and wavelength range listed on the laser safety labels that are affixed to the laser.

CAUTION

![]() Damage to the laser is possible, unless caution is employed when operating the device.

Damage to the laser is possible, unless caution is employed when operating the device.

The equipment is designed for: (1) Indoor Use, (2) Operation at less than 2000 meters altitude, (3) Over Voltage Category II, (4) Pollution Degree 2 Environment, and (5) Dry Locations. Refer to product specifications for additional information.

This equipment is not suitable for use in locations where children are likely to be present. Keep away from sources of shock or vibration.

Proper enclosures should be used to secure a laser safe work area. This includes but is not limited to laser safety signs, interlocks, appropriate warning devices and training/safety procedures. Do not operate with the output weld head at eye level. Ensure that laser enclosures are in place to protect personnel working in the area from eye damage.

Humidity: Do not expose the device to a high-moisture environment (>90% humidity).

Cooling and Temperature

The laser device is air-cooled. Operation at higher temperatures will accelerate aging, increase threshold current and lower slope efficiency. If the device is overheated, do not use it and call IPG for assistance. The device will turn emission off automatically and generate an alarm when the temperature of the laser exceeds 55°C.

Process By-Product

Ensure that the work surface is properly vented. When a laser beam reacts with any material, it can generate vapors, fumes, sparks and particulate debris. By-products from the laser process are often toxic and can pose additional safety hazards. These fumes must be evacuated from the work area by means of an extraction system.

IMPORTANT

![]() It is the responsibility of the end user to ensure proper disposal of waste debris and other by-products. Any extraction system must comply with local and health and safety regulations.

It is the responsibility of the end user to ensure proper disposal of waste debris and other by-products. Any extraction system must comply with local and health and safety regulations.

Additional Laser Safety Resources

For additional information regarding Laser Safety, refer to the following list:

Laser Institute of America (LIA)

13501 Ingenuity Drive, Suite 128

Orlando, Florida 32826

Phone: 407.380.1553, Fax: 407.380.5588 Toll Free: 1-800-34-LASER

Email: lia@laserinstitute.org

American National Standards Institute

ANSI Z136.1-2014, American National Standard for the Safe Use of Lasers (Available through LIA)

International Electro-technical Commission

IEC 60825-1, Edition 3.0

Safety of laser products - Part 1: Equipment classification, requirements and user's guide. (Available through LIA)

Center for Devices and Radiological Health

21 CFR 1040.10 - Performance Standards for Light-Emitting Products http://www.fda.gov/Radiation-EmittingProducts/default.htm

US Department of Labor - OSHA

Publication 8-1.7 - Guidelines for Laser Safety and Hazard Assessment http://www.osha.gov/

Laser Safety Equipment

Laurin Publishing,

Laser safety equipment and Buyer's Guides http://www.photonics.com/Directory/

IMPORTANT

![]() IPG Photonics recommends that the user of this product investigate all applicable local, state or federal requirements as well as facility or building requirements that might apply to installing or using a laser or laser device. Ensure that the standard you are using, such as ANSI, IEC, and OSHA, are current.

IPG Photonics recommends that the user of this product investigate all applicable local, state or federal requirements as well as facility or building requirements that might apply to installing or using a laser or laser device. Ensure that the standard you are using, such as ANSI, IEC, and OSHA, are current.