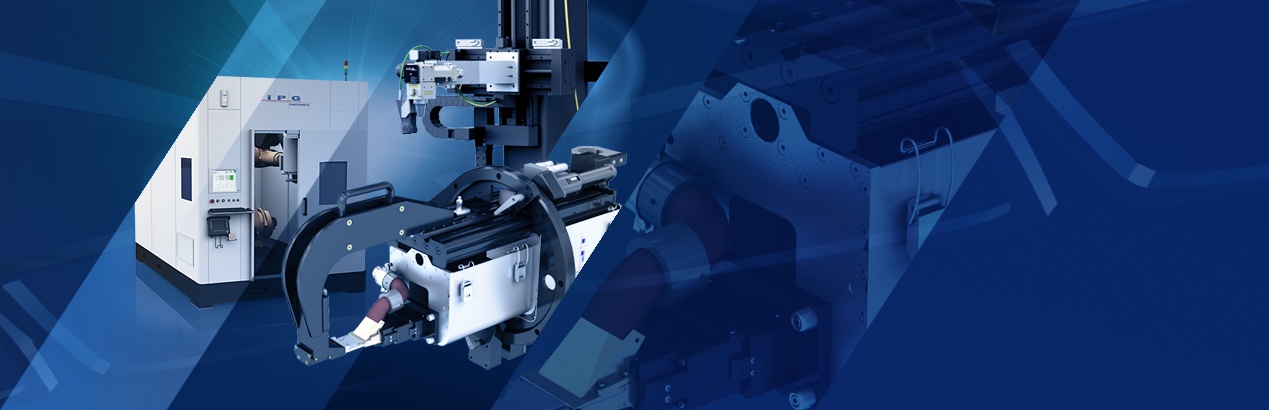

溶接・ブレージング

IPG Fiber Lasers are rapidly becoming the technology of

choice for welding components in automotive, aerospace,

railway, shipbuilding, oil & gas, defense, medical device,

consumer electronics and microelectronics industries.

IPG Welding Systems provide part-handling, beam

delivery and automation control in highly efficient,

robust and reliable production welding tools.

The line of products includes Laser Welding

Cells with a robot for welding large parts,

Multi-Axis workstations for welding of

smaller parts with higher precision,

Laser Seam Steppers for automotive

panel welding, and Tube and

Profile Welders.