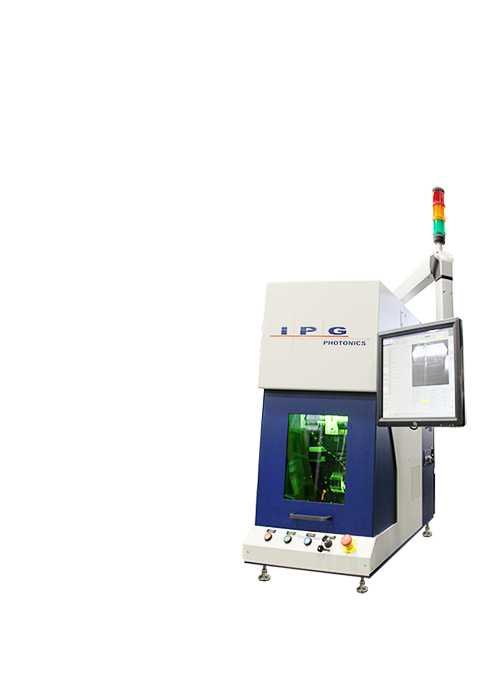

Multi-Axis Laser Processing Workcell

Welding, Cutting, Drilling, Cleaning

The Multi-Axis Workcells are compact, highly cost-efficient 2D and 3D CNC laser cutting tools and laser welding tools for both prototype and high-volume production environments.

| PROCESS | INDUSTRIES |

| • Spot Welding | • Medical Devices |

| • Seam Welding | • Electrical Enclosures |

| • 2D Cutting | • Electrical Contacts |

| • Tube Cutting | • Sensors & Transducers |

| • Via Drilling | • Automotive Component |

Welding, Cutting, Drilling & Cleaning.

Improves Weld Quality & Visual Finish.

| 2019 | ||

| September 24 - 26 |  |

|

| September 30 - October 3 |  |

Canadian Manufacturing Technology Show (CMTS)

|

| October 23 - 24 |  |

|

| November 5 - 8 |  |

|

| November 7 - 11 |  |

International Engineering Fair

|

| November 11 - 14 |  |

|

| December 12 - 14 |  |

Performance Racing Industry (PRI)

|

| 2020 |

|

|

| September 14 - 19 |  |

International Manufacturing Technology Show (IMTS)

|

| 2019 | ||

| September 24 - 26 |  |

|

| September 30 - October 3 |  |

Canadian Manufacturing Technology Show (CMTS)

|

| October 23 - 24 |  |

|

| November 5 - 8 |  |

|

| November 7 - 11 |  |

International Engineering Fair

|

| November 11 - 14 |  |

|

| December 12 - 14 |  |

Performance Racing Industry (PRI)

|

| 2020 |

|

|

| September 14 - 19 |  |

International Manufacturing Technology Show (IMTS)

|

Your information will be delivered.

We hope this guide helps you in your decision making process. If you have any questions about the Multi-axis or would like to request custom samples, please contact us at Sales.MultiAxis@ipgphotonics.com or 508-735-0968.

Would you like to share this info with your team? Our datasheets are conveniently formatted for easy sharing and printing.

Multi-axis Compact Workcell Datasheet

Thank you for your interest.

An IPG Laser Processing Specialist will be pleased to assist with your query. Please provide basic contact details below and indicate a time when it will be convenient for us to call you. Please indicate the subject closest to your topic of interest from the dropdown so that we can have the most appropriate specialist contact you.

IPG’s Multi-axis Workcell is an ideal processing system for manufacturers of medical devices, automotive components, electrical and electronic enclosures /packages and small appliance parts.

With three base platform sizes and standardized modules, these systems are readily configurable for your specific applications, enabling you to invest in processing capabilities optimally matched to your needs.

The Multi-Axis workcells are designed, built and supported by IPG Photonics, the World leader in fiber laser technology

With rugged industrial construction, these systems include a granite table for thermal and mechanical stability. High-accuracy linear-drive motors and low-mass processing head are optimized for the rapid motions associated with high-speed small part machining.

|

|

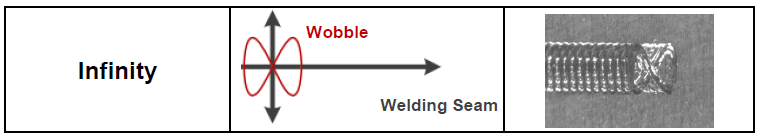

IPG’s Wobble welding heads are designed to provide the highest laser power handling capability in the industry in a completely sealed and lightweight package.

These process heads provide effortless integration with IPG lasers and offers improved weld quality and better visual finish. Available in multiple configurations with the broadest focus and collimator lens options, the Wobblers are the ultimate tool to weld a multitude of different material types and thicknesses.

Available Shapes

Shape: Infinity

Amplitude: 2 mm Diameter

Frequency: 300 Hz Wobble

Weld Speed: 3.5 m/min

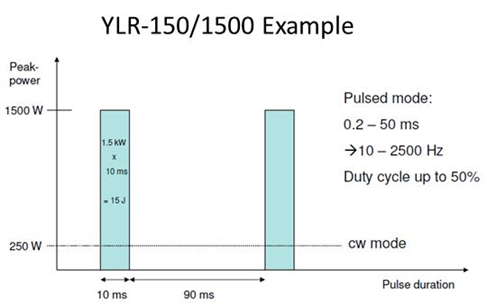

IPG’s Multi-axis Workcell is compatible with any IPG fiber laser up to a maximum average power of 6,000 W. Typically, applications require significantly lower power, and IPG offers a unique selection of laser types to perfectly match your application.

The precision part positioning of IPG’s Multi-axis Workcell combined with the high peak power QCW laser provides a highly flexible welding system compatible with all metal types. The highly efficient QCW lasers feature an adjustable output power with no changes in beam profile or quality, allowing versatility across all applications. The Multi-axis software provides advanced programmability of pulse duration and frequency characteristics with dynamic laser power control providing optimized, repeatable welding quality for all jobs.

|

Tell us about your application, whether it’s welding, cutting, drilling or marking, and we can send you a sample part produced on a Multi-axis system. Alternatively, let’s talk about running one of your parts.

For commonly used metals, we probably have the raw sheet in stock. For any exotic alloys or highly reflective parts you are having difficulty with, you might want to send us the material and let us show how IPG’s laser processing compares to alternate machining or joining techniques. |

|

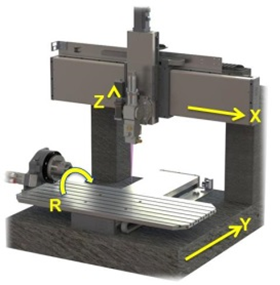

The modular design of the Multi-axis product family allows the user to select the best combination of motion systems for the job.

Up to four synchronized motion axis are available: X, Y, Z and rotation. Depending on the orientation of the rotary stage, the part can rotate about either the X or Z axis. Additionally, a non-synchronized option is available to provide tilting of the laser processing head (rotating around the Y axis.)

|

As your partner for precision laser processing systems, IPG is here to provide advice and guidance along the way. Sometimes it is helpful for the engineer to be able to visualize the job being discussed. Where this is the case, consider sending a DXF or even a simple sketch along with your question.

Frequent Discussion Topics Include:

|

|

IPG has assisted numerous customers obtain financing through close coordination with various leading lenders to the industrial equipment market. Customers can choose their own lender or a lender previously used by other IPG customers. IPG will assist Laser Systems customers wishing to accelerate a tool purchase, preserve working capital, or optimize tax benefits by collaborating closely with the customer’s lender to ensure a seamless, no-hassle customer experience. |

|

|

IPG’s customers have purchased Laser Processing Systems using a wide range of financing options. Financing terms and conditions previously offered to IPG’s customers by various lenders have included: |

|

|

|

|

LOAN Terms from 2-7 years |

LEASE

Terms from 2-7 years |

RENTAL Terms from 1-3 years |

|

• Fixed Rate allows customer to amortize equipment purchase over entire term of loan. |

• Lower payment options, with choice to purchase equipment at Fair Market Value OR Return equipment at end of term. |

• Customizable, allows for short term usage of equipment for a set time period |

|

To find out which lenders IPG customers have used previously or learn more about how IPG has assisted other customers, simply click the box in the IPG customer registration form, or contact your IPG representative at Sales.MA@IPGPhotonics.com. |

|

All financing is offered by independent, third-party lenders who are solely responsible for determining credit eligibility and financing terms. IPG assumes no liability for and expressly disclaims all liability relating to or arising out of financing, leasing or rental transactions between any third party lenders and IPG’s customers. |

IPG’s Multi-axis Laser Workcell is a highly cost-efficient tool for welding, cutting, and drilling a wide range of metal components, enclosures and fabrications. Configurable with our high efficiency CW lasers or our high peak power QCW lasers, the Multi-axis workcell provides fast processing of even highly reflective materials.

Please provide your company email address to receive a copy of the Multi-axis product family brochure.

** Your brochure will open in another tab, so please make sure to temporarily disable your pop-up blocker.

| Multi-axis Compact System for Laser Welding, Drilling or Cutting Applications | Multi-axis Micro System for Laser Welding, Drilling or Cutting Applications | |

| Weld Process Monitoring | Wobble & Seam Tracking Module | |

| Flat Plate Wobble Welding of Aluminum and Copper | Micro Tube Welding |

Sales.MultiAxis@IPGPhotonics.com

Popular Content

IPG regularly hosts Lunch & Learns, open houses and technology briefings that cover all aspects of laser welding, cutting, drilling and marking. Find an event near you.

A technique to significantly improve the quality of difficult-to-weld and dissimilar metal joining Seam Tracking extends process window for badly fitted parts.

A variety of financing options are available to help you fund your new laser system. You even have the opportunity to loan, lease, or rent.